Product Specifications

Material: High-strength alloy steel, corrosion-resistant alloy

Surface coating types: zinc plating, nickel plating, chrome plating

Tolerance range: in accordance with international standards

Processing methods: precision casting and machining

Quality inspection: ISO 9001 quality management system certification

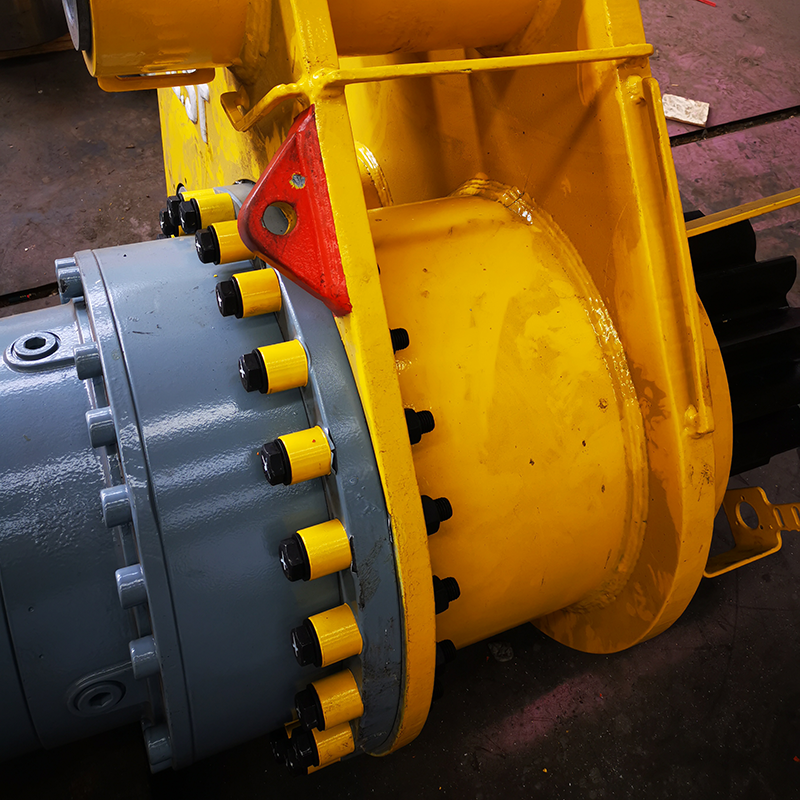

Plunger accessories usually refer to components used in mechanical equipment such as plunger pumps and plunger motors. Plunger pump is a common high-pressure pump that generates pressure through the reciprocating motion of the plunger in the pump cylinder, and is widely used in various occasions such as industry, agriculture, medicine, and daily life.

Plunger accessories may include the following types:

1. Plunger: It is the core component of a pump, usually made of wear-resistant materials such as stainless steel or ceramics, to withstand high pressure and high-frequency reciprocating motion.

2. Plunger rod: The driving part connecting the plunger and pump usually requires high strength and wear resistance.

3. Seals: Used to prevent medium leakage, usually made of rubber or other elastic materials.

4. Guide sleeve: used to guide the linear movement of the plunger, usually matching the material of the plunger to reduce wear.

5. Pump body and pump cover: They are the casing of the pump and need to have sufficient strength and sealing.

6. Driving device: including a crank, connecting rod, etc., which transfers power to the plunger and causes it to move back and forth.

When selecting plunger accessories, it is necessary to consider requirements such as working medium, pressure, flow rate, and frequency to ensure the performance and durability of the accessories. At the same time, it is also necessary to consider the reliability and cost-effectiveness of accessories to meet the needs of practical applications.

Wind turbines can be roughly divided into three parts: the wind rotor (including the tail rudder), the generator and the tower. The principle of wind power generation is to use wind power to drive the wind turbine blades to rotate, and then increase the speed of rotation through the speed increaser to drive the generator to generate electricity.

Wind power generation refers to the conversion of wind kinetic energy into electrical energy. Wind energy is a clean and pollution-free renewable energy that has been used by people for a long time. China is rich in wind energy resources, and the exploitable wind energy reserves are about 1 billion kW, of which the land wind energy reserves are about 253 million kW (calculated based on data at a height of 10m above the ground on land), and the offshore wind energy reserves that can be developed and utilized are about 750 million kW, totaling 1 billion kW. At the end of 2003, the national installed power capacity was about 567 million kW.

Offshore wind power is an important field for the development of renewable energy, an important force to promote the advancement of wind power technology and industrial upgrading, and an important measure to promote the adjustment of energy structure. China is rich in offshore wind energy resources. Accelerating the construction of offshore wind power projects is of great significance to promoting the control of atmospheric haze in coastal areas, adjusting the energy structure and transforming the economic development model.

1. The wind-solar hybrid power generation model is mainly composed of wind turbines, solar photovoltaic battery groups, controllers, batteries, inverters and other parts. The system is a composite renewable energy power generation system that integrates multiple energy generation technologies and systems such as wind energy, solar energy and batteries. The model is divided into regions with offshore wind-solar hybrid power generation areas, onshore wind-solar hybrid power generation areas, and single wind turbine cabin cross-sectional models; the model equipment is made completely according to the appearance structure, and the production ratio is scaled according to the size. The project model demonstration is set off by greening, environment, ocean, and building scenes;

2. The wind power generation model converts wind energy into electrical energy through wind turbines. The sand table is designed in proportion to the prototype layout of large wind farms (marine wind power, land wind power); including multiple wind turbines, booster station facilities, transmission lines, and field environment; the layout of wind turbines is sand table-style, and the layout of each wind turbine is staggered; wind turbine electric rotation demonstration.

3. Wind turbine cabin model: A large-scale wind turbine model is manufactured at an appropriate location in the wind farm area, with a cabin section that can display the hub, gearbox, cabin cover, coupling, electronic control system, generator, base, blades, tower, etc. in the unit.

Offshore Wind Power Dual Pillars: A Stable and Reliable Offshore Wind Power Foundation Structure

1、 Design principles

The offshore wind power double column foundation structure consists of two parallel columns, commonly referred to as “double columns”, which are fixed on the seabed to support the tower and blades of the wind turbine. The design of the double column foundation aims to provide sufficient stability and bearing capacity to cope with the natural forces of wind, waves, currents, and tides in the marine environment. It is usually used in shallow waters because this foundation structure is relatively simple and has lower construction and installation costs.

2、 Advantages and disadvantages

The dual column foundation structure of offshore wind power has the following advantages:

1. Structural stability: The double column foundation structure adopts a parallel column design, which can provide better stability and bearing capacity, and can cope with natural forces such as wind, waves, ocean currents, and tides in the marine environment.

2. Easy to build and install: Compared to other offshore wind power foundation structures, the construction and installation cost of double column foundation structures is lower, and the construction process is relatively simple.

3. Easy maintenance: The maintenance of the double column foundation structure is relatively simple and can be inspected and maintained by divers or drones.

However, the double column foundation structure also has some drawbacks:

1. High requirements for seabed geological conditions: The double column foundation structure requires detailed investigation and design to ensure its stability even in poor seabed geological conditions.

2. Safety and stability may be affected under extreme weather conditions: Double column foundation structures may be affected under extreme weather conditions and require corresponding safety measures.

3、 Application situation

Double column foundation, as a common offshore wind power foundation structure, has been widely applied and promoted worldwide. For example, in China’s offshore wind power projects, double column foundation structures have been widely adopted. In addition, double column foundation structures have also been widely used in offshore wind power projects in Europe, North America, and other regions.

In summary, the dual column foundation structure of offshore wind power has the advantages of structural stability, easy construction and installation, and easy maintenance, making it a reliable offshore wind power foundation structure. When selecting offshore wind power infrastructure, it is necessary to evaluate and select based on specific project requirements and environmental conditions.

Contact Information for Column Plunger Seals Inquiries

For more information about Column Plunger Seals or to obtain customized solutions, please contact us:

- Contact Person: Frank

- Tel: 86-510-82305188-8060

- Mobile: 86-18605101203

- Mail: frankgu@cmecwuxi.com

- Address: 15-16F, Building A10, No. 777, JianZhu West Road, Binhu District, Wuxi, Jiangsu, 214072. P.R. China

We look forward to collaborating with you and providing robust support and services for your business.