A heat exchanger is a device that transfers part of the heat from a hot fluid to a cold fluid, also known as a heat exchanger. Heat exchangers play an important role in chemical, petroleum, power, food, and many other industrial productions. In chemical production, heat exchangers can be used as heaters, coolers, condensers, evaporators, and reboilers, and are widely used.

Suitable for heat exchangers with different media, working conditions, temperatures, and pressures, and with different structural types. The specific classification of heat exchangers is as follows:

Classification based on heat transfer principles

1. Inter wall heat exchanger is a type of heat exchanger where two fluids with different temperatures flow in a space separated by the wall, conducting heat on the wall and convection on the wall surface. The heat is transferred between the two fluids. Wall type heat exchangers include shell and tube type, sleeve type, and other types of heat exchangers. Wall type heat exchangers are the most widely used types of heat exchangers.

2. A heat storage heat exchanger is a heat storage body composed of solid materials, which transfers heat from a high-temperature fluid to a low-temperature fluid. The hot medium first reaches a certain temperature by heating the solid material, and then the cold medium is heated by the solid material to achieve the purpose of heat transfer. Regenerative heat exchangers include rotary and valve switching types.

3. Fluid connection indirect heat exchanger fluid connection indirect heat exchanger is a heat exchanger that connects two surface heat exchangers with a circulating heat carrier. The heat carrier circulates between the high-temperature fluid heat exchanger and the low-temperature fluid, receiving heat in the high-temperature fluid and releasing heat to the low-temperature fluid in the low-temperature fluid heat exchanger.

4. Direct contact heat exchanger, also known as hybrid heat exchanger, is an equipment where two fluids come into direct contact and mix with each other for heat exchange, such as a cold water tower, gas condenser, etc.

5. A compound heat exchanger is an equipment that combines two types of heat transfer methods: indirect steam surface heat transfer and direct mixed water flow heat transfer. Compared with the indirect heat transfer on the vapor surface, it has a higher heat transfer efficiency; Compared with direct mixing of steam and water for heat exchange, it has higher stability and lower unit noise.

Classified by purpose

1. A heater heats the fluid to the necessary temperature, but the heating fluid does not undergo any phase change.

2. The preheater preheats the fluid in advance, providing standard process parameters for process operations.

3. A superheater is used to heat a fluid (process gas or steam) to an overheated state. 4. The evaporator is used to heat the fluid to a temperature above the boiling point, causing the fluid to evaporate, usually with phase changes.

Classified by structure

It can be divided into: floating head heat exchangers, fixed tube plate heat exchangers, U-shaped tube plate heat exchangers, plate heat exchangers, etc

Heat exchangers can be divided into three types based on different heat transfer methods: hybrid, thermal storage, and inter wall.

A hybrid heat exchanger is a heat exchanger that exchanges heat through direct contact and mixing of cold and hot fluids, also known as a contact heat exchanger. Because timely separation is necessary after mixing and exchanging heat between two fluids, this type of heat exchanger is suitable for heat exchange between gas and liquid fluids. For example, in the cooling towers used in chemical and power plants, hot water is sprayed from top to bottom, while cold air is sucked in from bottom to top. On the surface of the water film or droplets of the filling material, the hot water and cold air come into contact for heat exchange. The hot water is cooled, the cold air is heated, and then separated in a timely manner depending on the density difference between the two fluids.

A thermal storage heat exchanger is a type of heat exchanger that utilizes alternating flow of cold and hot fluids through the surface of the thermal storage material (packing) in a thermal storage chamber, in order to exchange heat, such as a thermal storage chamber for preheating air below a coke oven. This type of heat exchanger is mainly used to recover and utilize the heat from high-temperature exhaust gas. Similar equipment aimed at recovering cold energy is called a cold storage device, which is often used in air separation devices.

A wall type heat exchanger is a type of heat exchanger where the cold and hot fluids are separated by solid walls and heat exchange occurs through the walls. Therefore, it is also known as a surface type heat exchanger, and this type of heat exchanger is the most widely used.

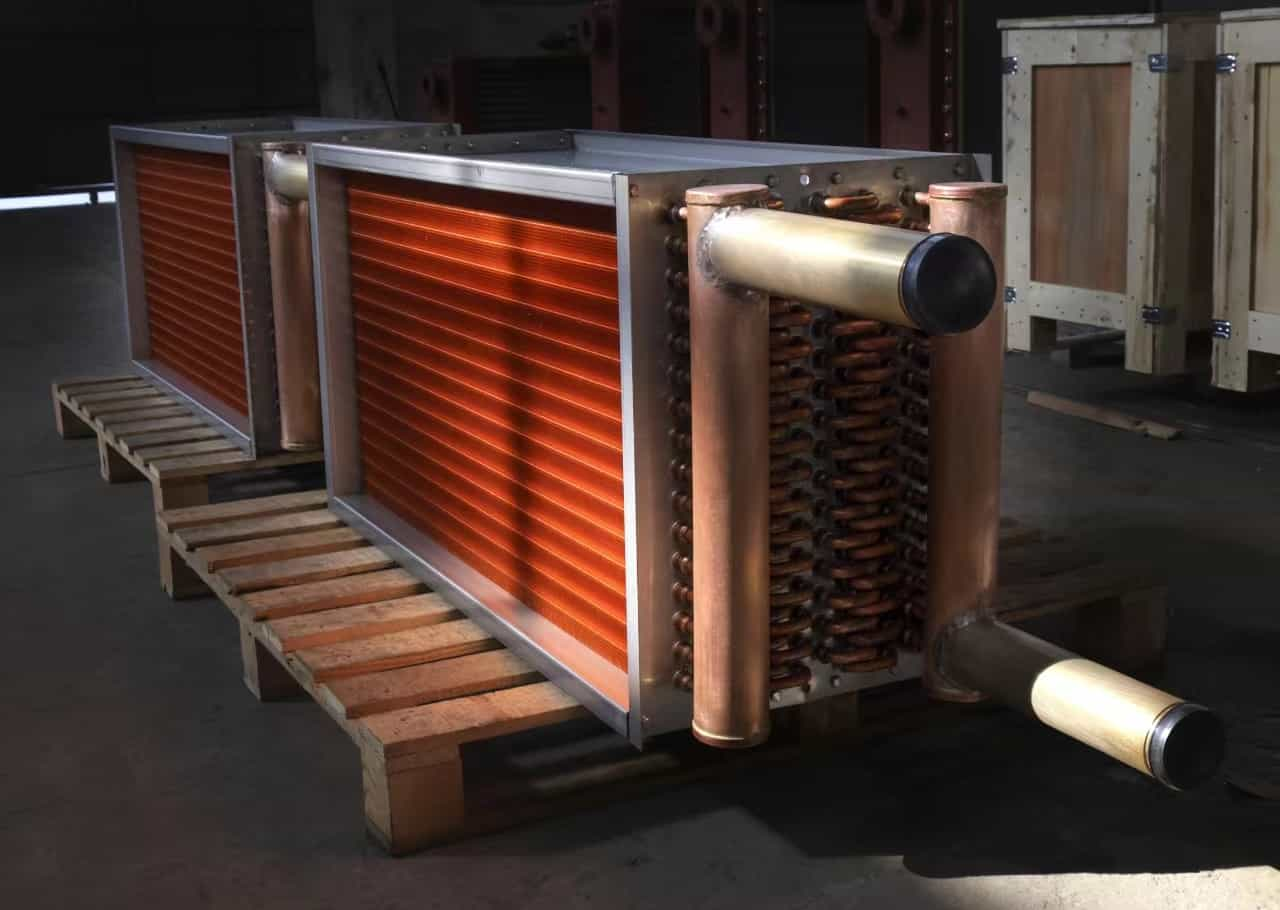

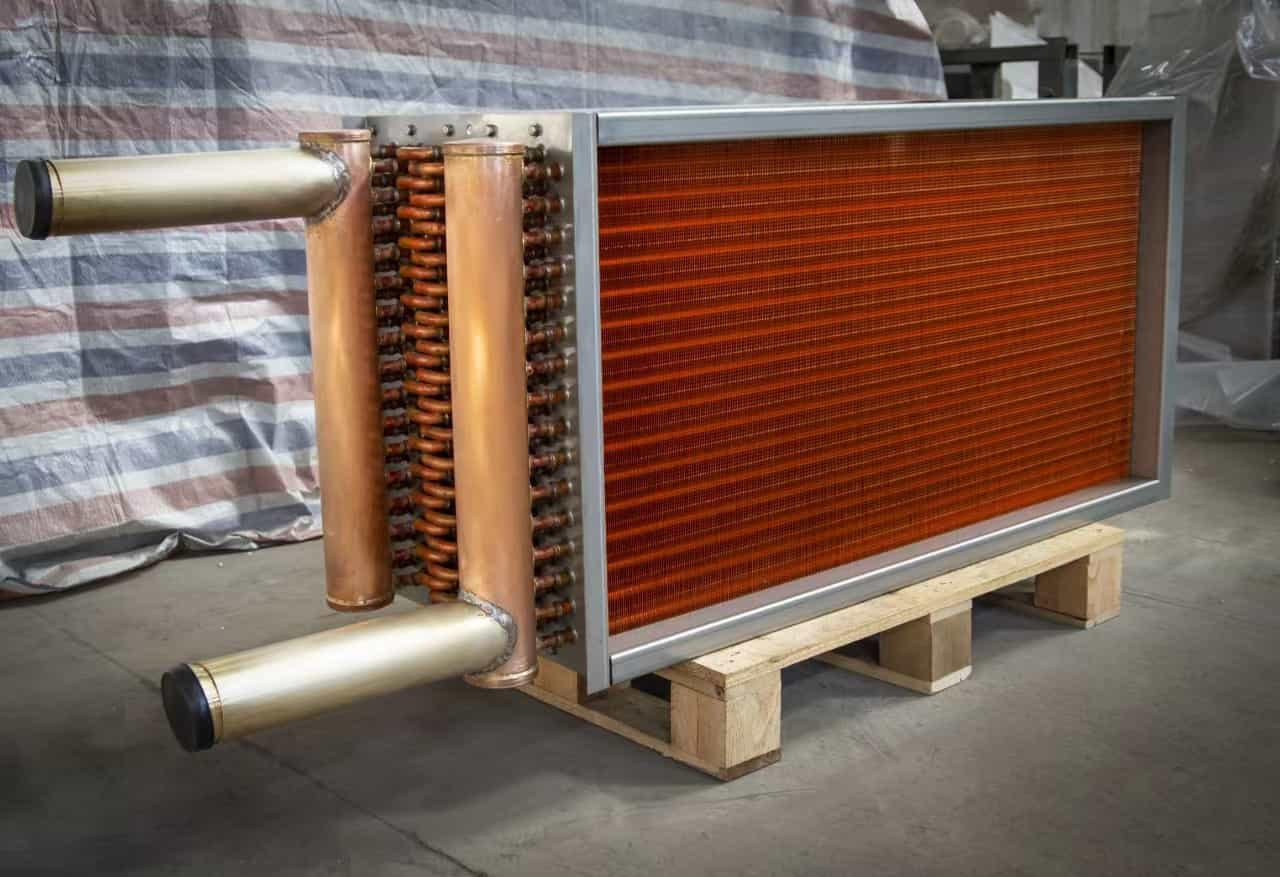

Wall type heat exchangers can be divided into tube type, plate type, and other types based on the structure of the heat transfer surface. Tube heat exchangers use the surface of the tube as the heat transfer surface, including serpentine tube heat exchangers, tubular heat exchangers, and shell and tube heat exchangers; Plate heat exchangers use the plate surface as the heat transfer surface, including plate heat exchangers, spiral plate heat exchangers, plate fin heat exchangers, plate shell heat exchangers, and umbrella plate heat exchangers, etc; Other types of heat exchangers are designed to meet certain special requirements, such as scraped surface heat exchangers, rotary plate heat exchangers, and air coolers.

There are generally two types of relative flow directions for fluids in heat exchangers: forward flow and reverse flow. When flowing downstream, the temperature difference between the two fluids at the inlet is maximum and gradually decreases along the heat transfer surface, until the temperature difference at the outlet is minimum. When in reverse flow, the temperature difference distribution between the two fluids along the heat transfer surface is relatively uniform. Under the premise that the inlet and outlet temperatures of cold and hot fluids are constant, when both fluids have no phase transition, the maximum and minimum uniform temperature difference in countercurrent flow is the same.

Under the premise of completing the same heat transfer, using countercurrent can increase the uniform temperature difference and reduce the heat transfer area of the heat exchanger; If the heat transfer area remains unchanged, using counter flow can reduce the consumption of heating or cooling fluids. The former can save equipment costs, while the latter can save operating costs, so reverse flow heat exchange should be used as much as possible in design or production use.

When there is a phase change (boiling or condensation) between cold and hot fluids, and only the latent heat of vaporization is released or absorbed during the phase change, the temperature of the fluid itself does not change. Therefore, the inlet and outlet temperatures of the fluid are equal. At this time, the temperature difference between the two fluids is independent of the choice of fluid flow direction. In addition to the upstream and downstream flows, there are also flow directions such as cross flow and turbulence.

Reducing the thermal resistance in inter wall heat exchangers to improve the heat transfer coefficient is an important issue during the heat transfer process. The thermal resistance mainly comes from the thin layer of fluid (called the boundary layer) adhered to the heat transfer surface on both sides of the intermediate wall, and the fouling layer formed on both sides of the wall during the use of the heat exchanger. The thermal resistance of the metal wall is relatively small.

Increasing the flow velocity and disturbance of the fluid can thin the boundary layer, reduce thermal resistance, and improve the heat transfer coefficient. However, increasing the fluid flow rate will increase energy consumption, so a fair coordination should be made between reducing thermal resistance and reducing energy consumption during design. To reduce the thermal resistance of dirt, it is possible to delay the formation of dirt and clean the heat transfer surface on schedule.

Generally, heat exchangers are made of metal materials, among which carbon steel and low alloy steel are mostly used to manufacture medium and low pressure heat exchangers; In addition to being mainly used for different corrosion resistance conditions, austenitic stainless steel can also be used as a material that is resistant to high and low temperatures; Copper, aluminum, and their alloys are commonly used in the manufacturing of low-temperature heat exchangers; Nickel alloy is used under high temperature conditions; In addition to making gasket parts, some non-metallic materials have been used to make corrosion-resistant heat exchangers, such as graphite heat exchangers, fluoroplastic heat exchangers, and glass heat exchangers.

The main application areas of heat exchangers

1、 Chemical industry

Heat exchangers are widely used in the chemical industry and can be used in multiple processes such as condensation, evaporation, crystallization, drying, and pyrolysis. Common applications include steam heating, coolant recovery, concentration, heating and cooling, etc. Heat transfer can be achieved through heat exchangers, which can reduce harmful gas emissions and improve production efficiency.

2、 Energy industry

In the energy industry, the application of heat exchangers mainly includes oil, natural gas, nuclear energy, wind energy, solar energy, etc. Heat exchangers can be used for heating, cooling, and distillation of petroleum and natural gas. They can recover waste heat and provide thermal energy to other equipment, achieving effective energy utilization.

3、 Environmental protection industry

Heat exchangers also have important applications in the environmental protection industry, which can be used in various aspects such as wastewater treatment, gas purification, and sludge drying. The application of heat exchangers can reduce the discharge of waste gas, wastewater, and slag, reduce pollution, and improve environmental protection effectiveness.

4、 Food and pharmaceutical industries

In industries such as food and medicine, heat exchangers are mainly used for heating, cooling, evaporation, concentration, and other processes. During food processing, heat exchangers can be used to disinfect and sterilize, improving the quality and safety of food; In the pharmaceutical industry, heat exchangers can control reaction temperature, achieve precision manufacturing of drugs, and improve product quality.

5、 Construction industry

In the construction industry, heat exchangers are mainly used in fields such as HVAC and air conditioning. By using a heat exchanger, air heating, cooling, dehumidification, and other functions can be achieved in situations where there is a large temperature difference between indoors and outdoors, improving the indoor environment and enhancing comfort.

Contact Information for Shell and Tube Heat Exchanger Inquiries

For more information about shell and tube heat exchanger or to obtain customized solutions, please contact us:

- Contact Person: Frank

- Tel: 86-510-82305188-8060

- Mobile: 86-18605101203

- Mail: frankgu@cmecwuxi.com

- Address: 15-16F, Building A10, No. 777, JianZhu West Road, Binhu District, Wuxi, Jiangsu, 214072. P.R. China

We look forward to collaborating with you and providing robust support and services for your business.