Product Specifications

Material: High-strength alloy steel, stainless steel

Surface coating types: galvanizing, chrome plating, nickel plating

Tolerance range: in accordance with international standards

Processing methods: precision casting and machining

Quality inspection: ISO 9001 quality management system certification

Offshore platform classification

According to whether its position is fixed or not, it is divided into fixed offshore platform and floating offshore platform.

Fixed offshore platform

The position remains unchanged throughout the service life, and its forms include pile type, rope type and gravity type.

Pile platform consists of a cap and pile foundation. Pile foundation includes wood pile, steel pile and reinforced concrete pile. It is driven into the seabed during construction, and the cap is installed on it. The rope platform is also called mooring tower platform. A prefabricated steel tower is placed on the seabed foundation block and anchored and tightened with steel cables in different directions. The gravity platform relies on the weight of the platform itself to sit firmly on the solid soil layer on the seabed, and has a strong ability to resist storms and waves.

(I) Pile platform

It consists of a cap (upper deck) and pile foundation. According to the material of the pile, it is divided into wood pile platform, steel pile platform and reinforced concrete pile platform. In the late 1940s, the jacket platform appeared. It was first welded into a cone-shaped space frame with steel pipes on land, then transported or floated to the offshore site. After it was in place, steel piles were driven into the seabed from the jacket, and then the deck was installed on the top. The tower platform that appeared in the 1970s is composed of a vertical jacket and several groups of bottom piles. The bottom piles are driven into the seabed along the outer periphery of the jacket. Pile platforms have been widely used in the construction of offshore docks, lighthouses, radar stations, hydrological and meteorological observation stations, etc. Among them, jacket platforms and tower platforms are mostly used for drilling and extracting submarine oil or natural gas. The main advantage of this structure is that the wave and water flow loads are small, but the cost increases exponentially with the water depth, and the water depth is limited.

(ii) Tension rope platform

Also known as the moored tower platform, it is a prefabricated steel tower body placed on the seabed foundation block, and anchored and tightened with steel cables around it. It is suitable for deep water areas.

(iii) Gravity platform

It relies on the platform’s own weight to sit firmly on the solid soil layer on the seabed. The bottom of this platform is a base composed of one or more reinforced concrete caissons, on which there are steel columns or reinforced concrete columns to support the upper deck. Since the entire structure is relatively large, the base is generally built in a mud dock excavated on the shore, then towed to a sheltered deep water area to connect it, and then floated to the site, loaded and sunk. This platform is generally used as an underwater oil storage tank or for drilling and extracting underwater oil. Its main features are strong ability to withstand storms and wave attacks, durable structure and low maintenance costs, but it is necessary to excavate a dock pit on the shore and have deep water construction waters near the shore, so the height of the structure is limited.

Floating offshore platform

A floating offshore platform is a large floating body, some of which can be moved and some cannot. A movable floating platform, also known as a mobile platform, is developed to meet the needs of frequent changes in locations for offshore operations such as exploration, construction, and maintenance.

The existing mobile platforms are divided into four types: bottom-sitting, self-elevating, semi-submersible and ship-type.

① The bottom-seated platform (also known as the floating platform) is mostly used in shallow waters. Its upper part is the working deck, and the lower part is a pontoon that also serves as a sinking pad, with columns or trusses in the middle. During operation, water is poured into the pontoon to make it sit on the seabed; after operation, the water in the box is pumped out, and the platform rises by its own buoyancy.

② The self-elevating platform adapts to a wide range of water depths. When floating, it is a barge. It is equipped with several cylindrical or truss pile legs on its four sides, and the lifting and lowering are controlled by gears, racks or hydraulic mechanisms. During operation, the pile legs are lowered and inserted into the seabed to a certain depth, so as to lift the bottom of the ship out of the water and become the working deck. After operation, the hull is lowered, the pile legs are pulled up, and it can be towed to a new location. The pile legs with a box-shaped sinking pad at the bottom are called sinking pad self-elevating platforms, and those without sinking pads are called pile-inserted self-elevating platforms.

③ Semi-submersible platforms are mostly used in deep waters, and are also composed of three parts: the upper working deck, the lower floating structure, and the middle column or truss. The lower floating structure is divided into two types: lower hull type and pontoon type. The lower hull type is more conducive to navigation, so the newly built self-propelled semi-submersible platforms mostly adopt the double lower hull type. This type of platform is in a semi-submerged state during operation, using anchoring positioning or dynamic positioning. After the operation, the water in the ballast tank is discharged, and it floats to the towing waterline, and then the anchor can be retracted and moved. A few semi-submersible platforms built in the past have the function of sitting on the bottom, and can also be located on the seabed in shallow waters for operation.

④ The ship-type platform (i.e., drilling ship) is an operating platform added to an ordinary ship. The ship is divided into a single body and a double body. It can generally be self-propelled, and anchoring positioning or dynamic positioning is used during operation. The movable floating platform is most widely used in submarine oil and natural gas exploration.

Self elevating offshore platforms mainly consist of sinking pads, pile legs, lifting devices, platforms (modules), etc.

1. Sinking pad: The sinking pad of a self elevating platform needs to sink into the seabed, and based on this, a transmission mechanism is used to raise and lower the platform. Therefore, except when the platform needs to move the work site, the main consideration for this sinking pad is not hydrodynamic characteristics, but the pressure magnitude after it sinks to the seabed. For this reason, the sinking pads of self elevating platforms are generally designed as whole blocks, with A-shaped shapes commonly seen, and their basic structural form is still similar to the platform (module). The sunken cushion mainly contains ballast water tanks, and some compartments are also used for other purposes.

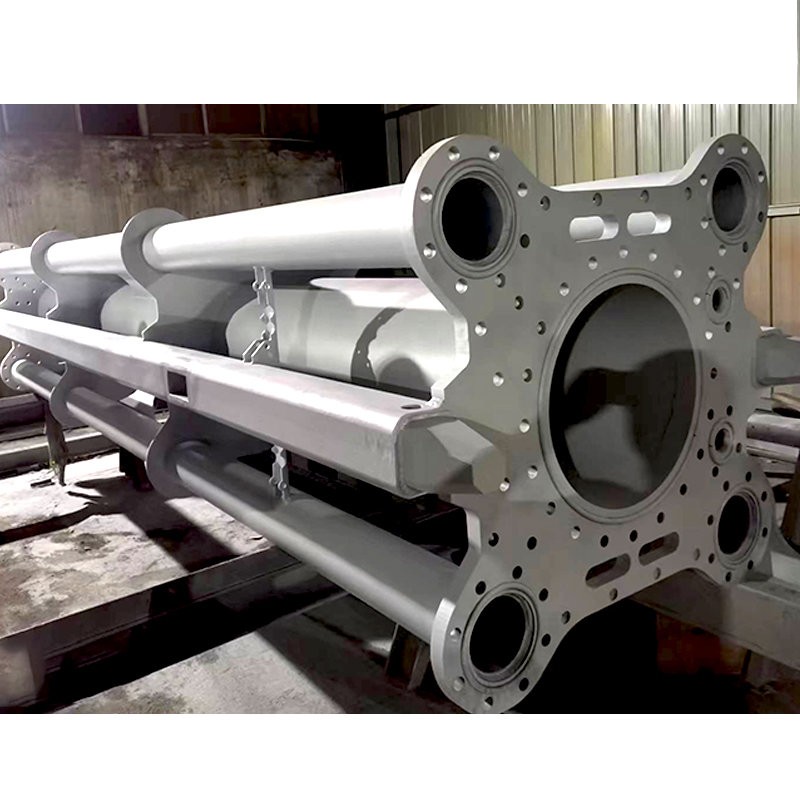

2. Pile leg: It is the column of a self elevating platform, which not only serves as a column, but also serves as a guide and lifting device during platform lifting. The number of pile legs varies from three to four, but in most cases, a three column style is used, which is beneficial for adjusting the level when the platform body rises or falls. The structural forms of pile legs can be further divided into two categories: truss pile legs and cylindrical pile legs. The truss type pile leg is composed of a main chord tube, a main tension brace tube, and a horizontal tension brace tube, and is equipped with a toothed strip plate (double-sided teeth) on the main chord tube; The cylindrical pile legs are made of steel plates to form a closed cylindrical structure, and then gear racks (single sided teeth) are welded on the axial outer wall of the cylinder according to the required amount. To reduce the impact of waves on the pile legs, truss structures are mostly used. There are components related to the self lifting device on the pile legs, and the triangular truss pile legs are generally equipped with racks to match the gears in the self lifting device; A type of cylindrical pile leg that has a flat rectangular hole and is matched with a wedge block pin in the self lifting device.

3. Lifting device: The lifting device is installed at the connection between the platform body and the pile legs. The lifting device can enable the pile legs and platform body to move up and down relative to each other, and place the platform body in a specific position on the pile legs. The commonly used lifting devices include electric hydraulic and electric gear rack type. The lifting device suitable for truss type self elevating platforms is an electric gear rack type, which is driven by an electric motor through a reduction mechanism to rotate the gears, causing them to mesh with the racks on the pile legs, thereby achieving relative motion between the platform body and the pile legs. When the electric motor is in the braking state, the platform can be fixed in this position. In order to mitigate the impact, buffer pads are installed on both the upper and lower parts of the lifting device gear frame.

4. Platform (Module): The flat shapes of a platform generally include triangles, rectangles, and pentagons. A platform is usually a single deck box structure with a single or double bottom, and the arrangement of its internal transverse and longitudinal bulkheads depends on its operation and layout requirements. In order to reduce the oscillation of the liquid in the cabin during platform movement, sometimes anti oscillation bulkheads are also installed in larger liquid cabins. The bottom plate, bulkheads, decks, etc. of the main structure are also equipped with reinforcement materials like ordinary ships. On the secondary module, there are pile legs passing through an opening, which is called the fixed pile area. Its structure is correspondingly strengthened to ensure the safety, stability of the self lifting mechanism and the integrity of the deck. The relative position control of several fixed pile areas on the same platform is extremely strict to ensure smooth platform lifting during future operation.

Analysis of the types and advantages and disadvantages of self elevating platform pile legs

There are two basic types of self elevating platform pile legs: truss pile legs and cylindrical pile legs.

The truss type pile leg structure is composed of chord tubes and support tubes. The support tubes can resist the shear stress of the pile legs, while the chord tubes mainly resist axial and bending stiffness. This structure achieves the optimal configuration of steel utilization, reduces structural mass, and reduces drag load [3]. Its cross-section is triangular or square, and the working water depth is within 100 meters. Generally, a pile leg box is installed at the bottom of the pile leg, and a bottom cushion type is used for working water depth within 150 meters.

The cylindrical pile legs are composed of hollow steel pipes with reinforced structures inside, and the outer shell is equipped with racks or openings to achieve the lifting and lowering of the ship. The number of pile legs is generally 3-4, with a maximum of 14-18. The diameter of the cylinder varies depending on the designed operating water depth. The biggest advantage of cylindrical pile leg structure is its small volume and occupies less deck area, making the construction process relatively simple. However, when resisting the same environmental load, cylindrical pile leg structure requires more steel.

The vast majority of self elevating drilling platforms in the world have three or four pile legs. The biggest advantage of a three pile structure is its excellent stability and minimal wave forces. In addition, it can save more deck space, reduce the number of lifting devices, reduce structural quality, and reduce costs. The biggest drawback of this structure is the need for pre ballast water tanks. The four pile structure almost does not require preloading tanks, and can be “diagonally loaded” with the main hull mass as the preloading weight. The four pile structure will be subjected to additional wind, wave, and current loads, which will also increase the towing mass.

Contact Information for Extension Tubes Inquiries

For more information about Extension Tubes or to obtain customized solutions, please contact us:

- Contact Person: Frank

- Tel: 86-510-82305188-8060

- Mobile: 86-18605101203

- Mail: frankgu@cmecwuxi.com

- Address: 15-16F, Building A10, No. 777, JianZhu West Road, Binhu District, Wuxi, Jiangsu, 214072. P.R. China

We look forward to collaborating with you and providing robust support and services for your business.