Crane is a type of equipment used for handling, grabbing, lifting, and lifting heavy objects, widely used in various fields such as industry, construction, ports, and manufacturing. According to different working principles and application scenarios, cranes can be classified into various types. The following is a detailed introduction to the classification of cranes and their application scenarios.

1. Bridge crane

Bridge crane is a lifting equipment that supports the lifting mechanism and operating mechanism in the form of a bridge. It includes single beam bridge cranes and double beam bridge cranes. Bridge cranes are commonly used in workplaces such as heavy industry, manufacturing, steel mills, and shipyards. Its characteristics are large lifting capacity, large span, and wide working range, suitable for the handling and lifting of large objects.

2. Tower crane

Tower cranes are cranes supported by vertical steel structures and are commonly used on construction sites and high-rise buildings. It has a large working range, high altitude, and can operate in the air. Tower cranes are mainly used for the lifting, assembly, and handling of building materials, improving the efficiency and quality of construction.

3. Mobile crane

A mobile crane is a lifting equipment that can move flexibly. It can be quickly moved to the location where work is needed as needed for various temporary lifting operations. Mobile cranes are generally composed of body, boom, and support legs, and are widely used in ports, warehouses, transportation, road construction, and other occasions.

4. Crawler crane

Crawler crane is a lifting equipment that uses tracks as the walking mechanism. Due to its good off-road performance and load-bearing capacity, crawler cranes have the characteristics of strong adaptability and good traffic capacity. It is widely used in construction sites, farmland irrigation, energy construction and other occasions.

5. Marine cranes

Marine cranes are mainly used for material loading, unloading, and handling in ports, docks, and ships. Marine cranes are usually installed at the hatch of ships, and their rotating arms can move horizontally and vertically to better complete loading and unloading operations.

6. Explosion proof crane

Explosion proof cranes mainly refer to cranes used in high-risk environments such as flammable and explosive environments. It has explosion-proof, anti-static, and anti-corrosion properties to ensure the safety of lifting operations in hazardous environments.

In addition to the common types of cranes mentioned above, there are also other special purpose cranes, such as tower cranes, gantry cranes, platform cranes, etc. They play important roles in different application scenarios based on different working principles and design characteristics.

In summary, cranes are important handling and lifting equipment with extensive applications in the industrial and construction fields. According to different working principles and application scenarios, cranes can be divided into various types, such as bridge cranes, tower cranes, mobile cranes, crawler cranes, marine cranes, and explosion-proof cranes. Each type of crane has its specific application scenarios and advantages, which can meet the needs of different industries, improve operational efficiency and safety.

Product Specifications

Material: High-strength alloy steel

Surface coating type: Anti-corrosion coating

Tolerance range: ±0.02mm

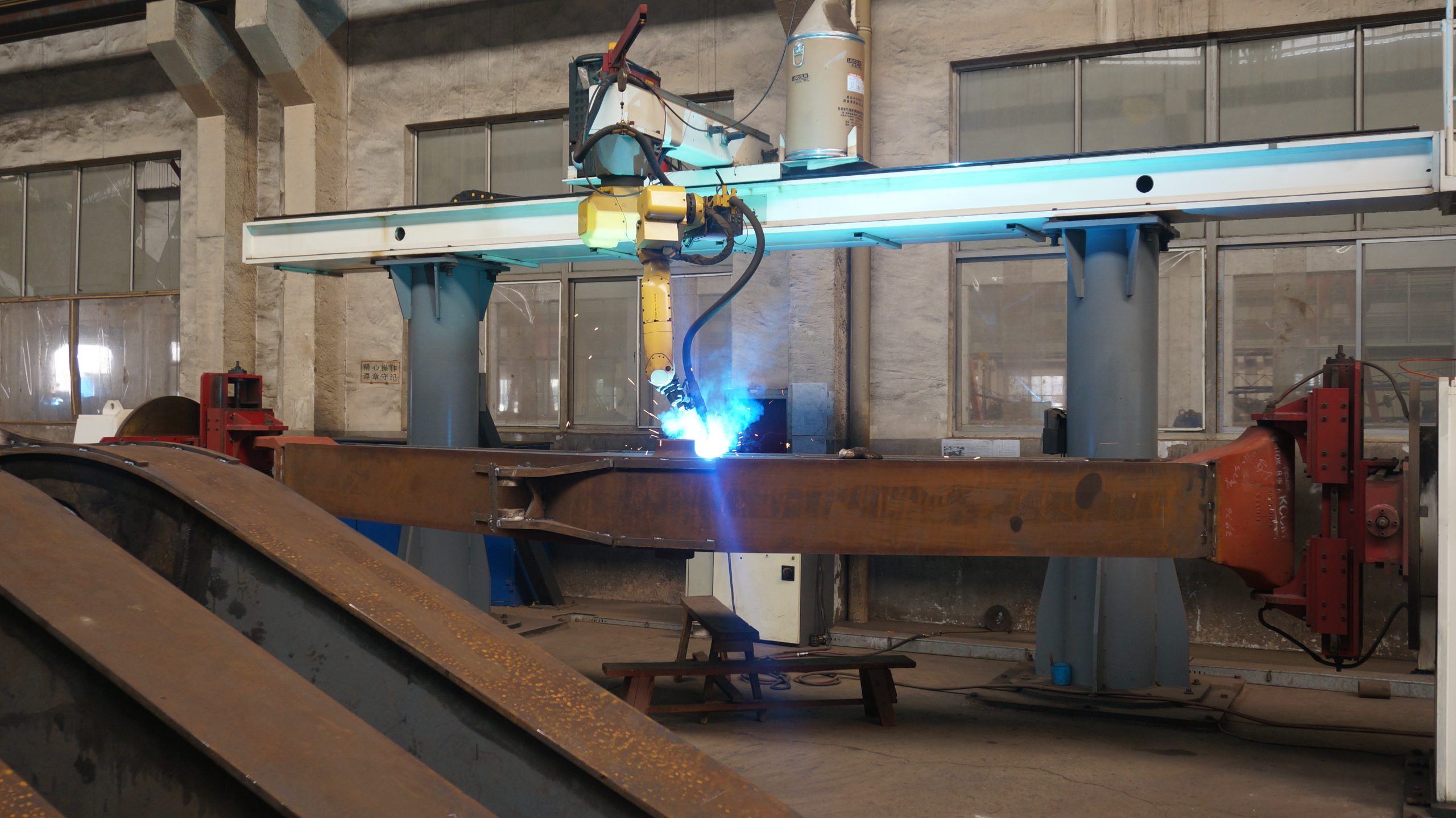

Processing method: Precision forging and welding technology

Quality inspection: Ultrasonic flaw detection and load testing

Marine cranes are important equipment on ships, used for loading and unloading goods and ship maintenance work. In order to ensure the safe and efficient operation of marine cranes, a series of technical standards have been formulated to standardize their design, manufacturing, installation, and use. This article will introduce the technical standards for marine cranes.

Firstly, the technical standards for marine cranes include design standards. The design standards mainly include the structural design, safety factor, service life, and other requirements of the crane. The structural design of the crane should comply with the ship design specifications, and consider factors such as the navigation status and cargo capacity of the ship to ensure the stability and reliability of the crane during ship operation. In addition, the design standards also require that cranes should have sufficient safety factors to cope with overloading or unexpected situations in unexpected situations. Meanwhile, the service life of cranes is also an important part of design standards, requiring them to maintain good operating conditions within the specified service life.

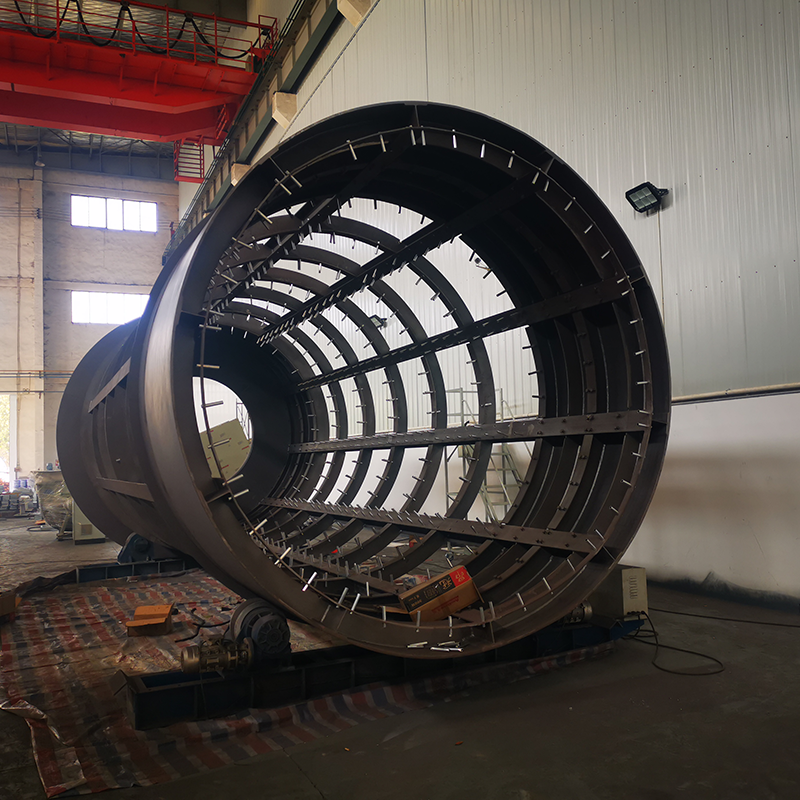

Secondly, the technical standards for marine cranes also include manufacturing standards. The manufacturing standards require that the manufacturing of cranes should comply with relevant international or industry standards, including material selection, processing technology, assembly technology, and other aspects. The material selection requirements shall comply with the relevant standards of ship materials, ensuring that the crane has good corrosion resistance and wind and wave resistance in the marine environment. The processing and assembly processes must comply with the relevant standards for crane manufacturing, ensuring that the various components of the crane can be accurately matched and operate stably and reliably.

In addition, the technical standards for marine cranes also include installation and usage standards. The installation standard requires that the installation of the crane should comply with relevant specifications, including installation position, fixing method, connection method, etc. The installation position requires consideration of the structure and stability of the vessel, ensuring that the installation of the crane does not affect the normal operation of the vessel. The fixing and connection methods must comply with relevant safety standards to ensure that the crane will not loosen or fall off during use. At the same time, the usage standards also include the daily maintenance and upkeep requirements of the crane, ensuring that the crane can maintain good condition during use.

In summary, the technical standards for marine cranes cover all aspects of design, manufacturing, installation, and use, aiming to ensure that cranes can operate safely and efficiently during ship operation. Developing and adhering to these technical standards is crucial for the design, manufacturing, and use of marine cranes, and is also an important measure to ensure the safety of ship operation. I hope this article can provide an understanding of the technical standards for marine cranes and be applied in practical work.

There are many standards for marine cranes, and the following are some common standards:

1. IMO MSC/Circ 1206: International Maritime Organization Rules for Ship Lifting Equipment and Devices

This standard specifies the safety and technical requirements for ship lifting equipment and devices, including the design, installation, maintenance, and operation of cranes.

2. GB/T 5378: “Complete set and quality requirements for small cranes”

This standard applies to the quality requirements for the complete set and accessories of small cranes used on ships, including crane spare parts, supporting equipment, and safety protection measures.

3. GB/T 18213-2018: Technical Conditions for Marine Cranes

This standard specifies the main technical parameters, models and specifications, work scope, installation and trial operation requirements, monitoring and maintenance, and usage of marine cranes.

4. API 2C: “American Petroleum Institute Specification for Offshore Jib Cranes”

This specification applies to the requirements for the design, manufacturing, testing, and installation of boom cranes on oil platforms, drilling vessels, and other marine construction facilities.

5. DNV GL: “Rules for Ship Lifting Equipment and Devices of Det Norske Veritas”

This rule is based on the International Maritime Organization (IMO) MSC/Circ Based on the “Rules for Ship Lifting Equipment and Devices” 1206, requirements for the design, manufacturing, installation, testing, maintenance, and use of ship lifting equipment and devices are stipulated.

Precautions for operating marine cranes

- Pay attention to the working environment conditions

Before using the marine crane, in order to work more safely, you must look at the surrounding environmental conditions, mainly wind, temperature and lightning

It is not allowed to use it in the case of lightning, thunderstorms and wind speeds greater than level 6

The ambient temperature is between -25℃ and +60℃.

- Pay attention to the requirements of the lifting wire rope before work

When lifting cargo, the angle of the lifting rope should not be too small or too large, and the angle should not exceed 120°, otherwise the lifting rope will be subjected to too much tension and easy to break

If the angle is too small, the lifting rope will be too long. When lifting, the inner arm elevation angle is too large, which can easily cause the system working pressure to be too high!

- Safety precautions during operation

- The operator must have a clear understanding of the marine crane and keep the crane in a high-efficiency state. If there are any questions, read the instruction manual in time

- The operator needs to undergo operation training before operation!

- Before starting the operation, be sure to check whether the lifting device (rope, hook, lifting point, etc.) has been designed for safety and meets the requirements for the weight and safety protection of the lifting cargo

- For insurance purposes, make sure that the cargo is firmly fixed!

- When the load is lifted or the crane is running, the operator must not leave the operating system

- Do not enter the operation and working range of the crane without the operator’s permission

- It is strictly forbidden to operate two actuators at the same time when lifting

- The operator needs to know the weight of the lifting load, which cannot exceed the load value calibrated by the crane, cannot lift the load at an angle (with a slope), and cannot drag or diagonally pull the load

- When the load leaves the ground, make sure there are no obstacles in the direction of the load!

- You can use a rope to guide the load at a certain distance, and it is strictly forbidden to lift people with a crane!

- The operator must understand the control valve on the safety device hydraulic cylinder. When the power circuit hose fails, the control valve can still control the current position of the heavy object and play a safety protection role!

Contact Information for Crane Boom Inquiries

For more information about Crane Boom or to obtain customized solutions, please contact us:

- Contact Person: Frank

- Tel: 86-510-82305188-8060

- Mobile: 86-18605101203

- Mail: frankgu@cmecwuxi.com

- Address: 15-16F, Building A10, No. 777, JianZhu West Road, Binhu District, Wuxi, Jiangsu, 214072. P.R. China

We look forward to collaborating with you and providing robust support and services for your business.