Product specifications

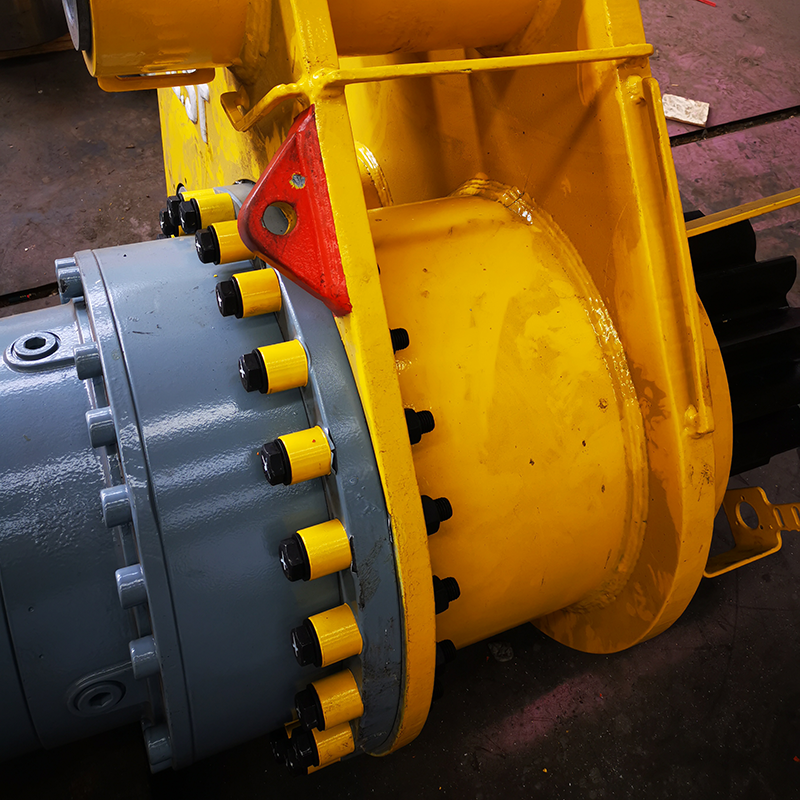

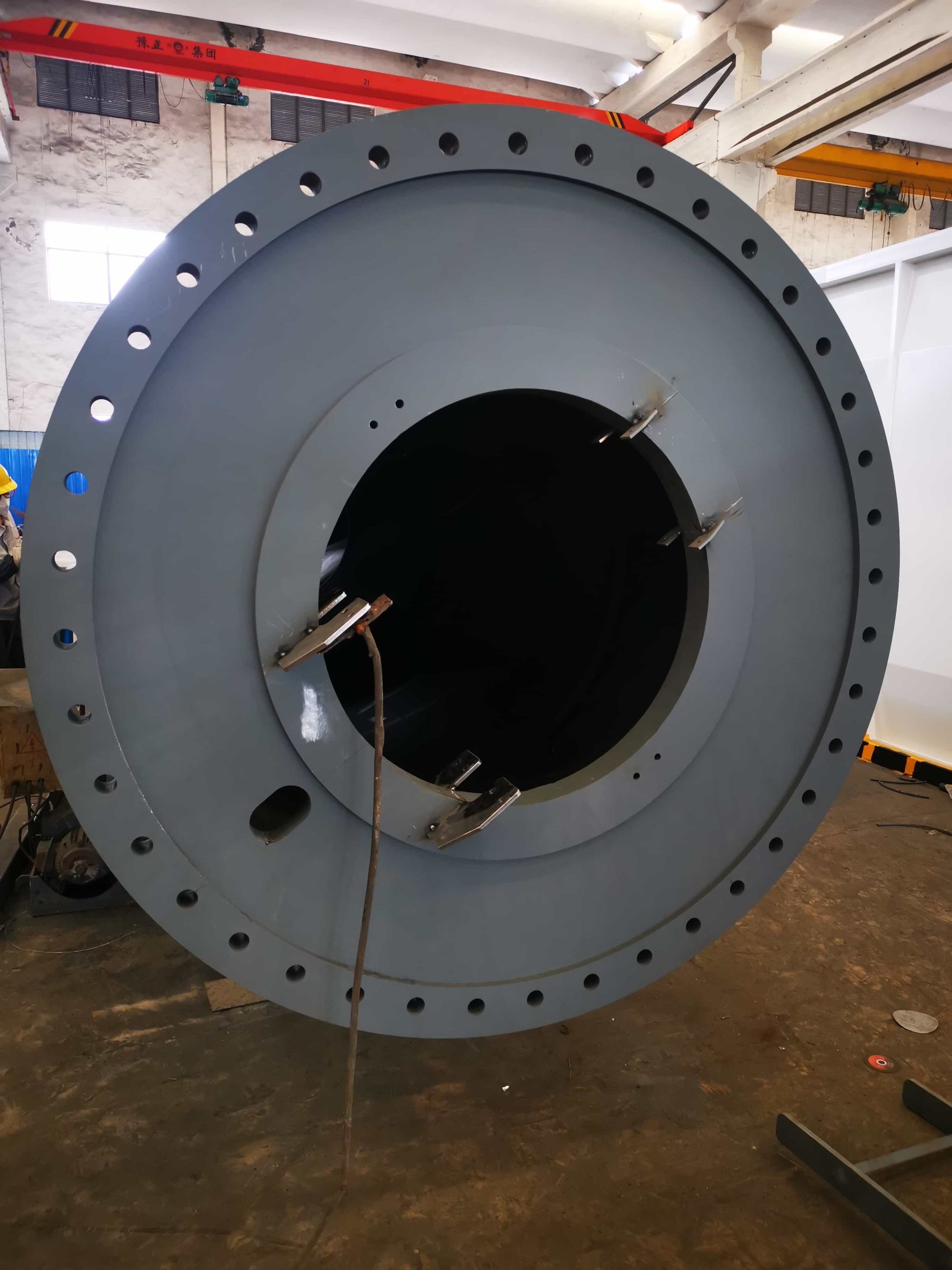

Material: high-strength alloy steel, high-wear-resistant ceramics

Surface coating types: zinc plating, chrome plating, titanium plating

Tolerance range: in accordance with international standards

Processing methods: precision casting and machining

Quality inspection: ISO 9001 quality management system certification

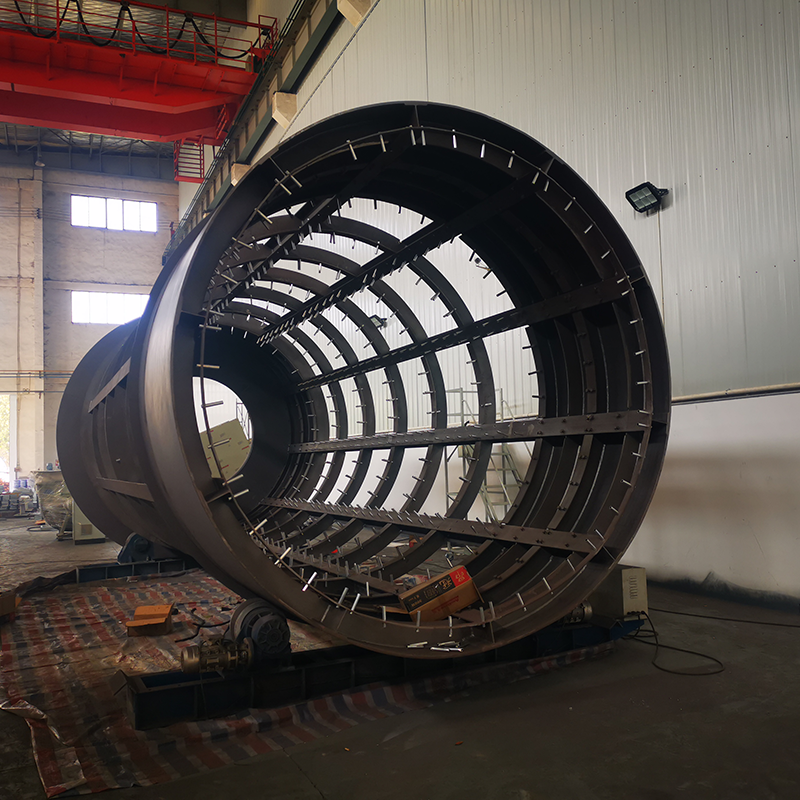

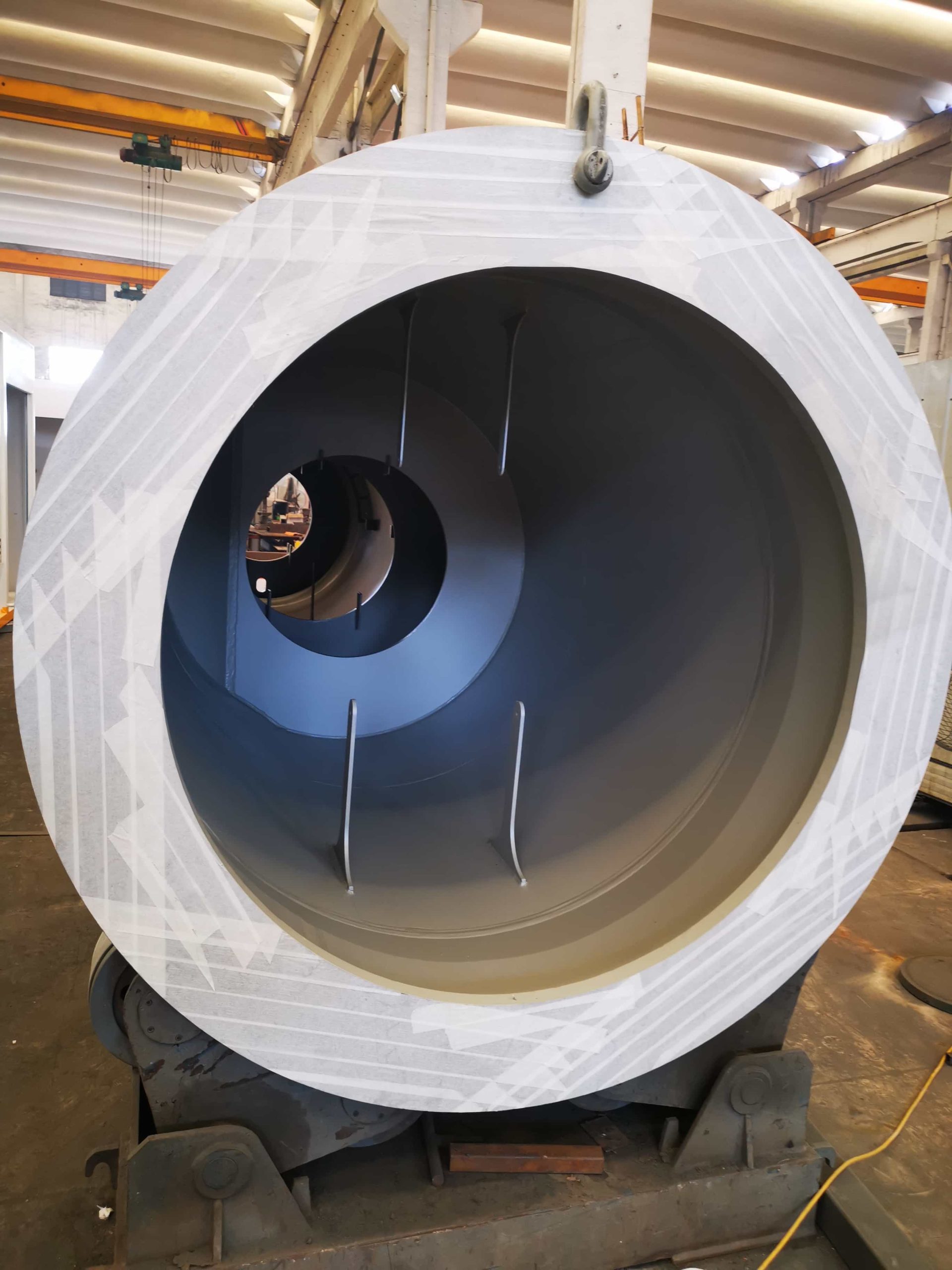

Sand mill, also known as bead mill, is mainly used for wet grinding of chemical liquid products. It is the most adaptable, advanced and efficient grinding equipment. It has the narrowest grinding chamber, the smallest lever gap and the most intensive grinding energy. With high-performance cooling system and automatic control system, it can realize continuous processing and continuous discharging of materials, greatly improving production efficiency. Sand mill is mainly composed of machine body, grinding cylinder, disperser, bottom valve, motor and feeding pump. The speed of feeding is controlled by valve.

Compared with grinding equipment such as ball mill, roller mill and colloid mill, sand mill has the advantages of high production efficiency, strong continuity, low cost and high product fineness. It has intensive grinding energy. With high-performance cooling system and automatic control system, it can realize continuous processing and continuous discharging of materials, greatly improving production efficiency. Sand mills can be divided into disc type, pin type, and disc type according to the structural shape of the stirring shaft; they can be divided into vertical type and horizontal type according to the layout of the grinding cylinder; they can be divided into laboratory type, small type, medium type, large type, and super large type according to the volume of the cylinder (or divided into 0.5l, 1L/30L, etc.); they can be divided into static and dynamic separation sand mills according to the medium separation method.

The working principle is to use a material pump to input the solid-liquid phase mixture after pre-dispersion and wetting treatment by the mixer into the cylinder. The material and the grinding medium in the cylinder are stirred by a high-speed rotating disperser, so that the solid particles in the material and the grinding medium produce stronger collision, friction, and shearing effects with each other, so as to accelerate the grinding of particles and disperse aggregates. The ground and dispersed materials are separated from the grinding media by a dynamic separator and flow out from the discharge pipe. The influence of sand mill working parameters on the ground materials, the flow rate of the sand mill affects the product fineness, output and particle size distribution. The medium size affects the grinding efficiency and product fineness. The stirring axis speed affects the grinding efficiency, material fineness and wear. The specific gravity of the medium affects the grinding efficiency and product fineness. The filling rate of the medium affects the grinding efficiency and the fineness of the product.

Advantages and characteristics of precision grinding machinery in terms of grinding accuracy:

High flatness: Precision grinding machinery can achieve extremely high flatness, and the flatness error can usually be controlled within 0.001 mm. This is because the mechanical equipment uses high-precision guide rails and precise control systems to ensure that the movement of the worktable and the grinding head is smooth and precise.

High parallelism: Precision grinding machinery can ensure that the two end faces of the workpiece have high parallelism, and the parallelism error is usually within 0.002 mm. High-quality mechanical structure and precise adjustment system make this possible.

Excellent surface roughness: Precision grinding machinery can achieve extremely fine surface roughness, usually up to Ra 0.1 µm or better. Through precise control systems and high-quality grinding tools, grinding machinery can leave uniform and smooth processing marks on the surface.

High dimensional accuracy: Precision grinding machinery can achieve very high dimensional accuracy, which can usually be controlled within ±0.005 mm. This is especially important for the processing of parts that require strict dimensional tolerances.

Stable repeat positioning accuracy: The repeat positioning accuracy of precision grinding machinery is usually within 0.002 mm, thanks to the high-precision servo system and feedback control system. This ensures that each processing can achieve consistent accuracy standards.

Automation and intelligence: Modern precision grinding machinery is usually equipped with advanced CNC systems, which can perform automated operations, reduce human errors, and improve production efficiency. In addition, some equipment also has intelligent monitoring and self-correction functions, which further improves processing accuracy and stability.

Multiple grinding methods: Precision grinding machinery can adopt a variety of grinding methods according to different processing requirements, such as plane grinding, cylindrical grinding, inner hole grinding and forming grinding, etc., to meet the processing of parts with various complex shapes and high precision requirements.

Due to these advantages, precision grinding machinery plays a key role in the manufacturing industry, ensuring the high quality and consistency of parts. For fields that require high-precision processing, precision grinding machinery is an indispensable equipment.

Contact Information for Grinding Machine Accessories Inquiries

For more information about Grinding Machine Accessories or to obtain customized solutions, please contact us:

- Contact Person: Frank

- Tel: 86-510-82305188-8060

- Mobile: 86-18605101203

- Mail: frankgu@cmecwuxi.com

- Address: 15-16F, Building A10, No. 777, JianZhu West Road, Binhu District, Wuxi, Jiangsu, 214072. P.R. China

We look forward to collaborating with you and providing robust support and services for your business.