Product specifications

Material: high-strength alloy steel, stainless steel, aluminum alloy, etc.

Surface coating types: anti-corrosion coating, wear-resistant coating, etc.

Tolerance range: ±0.01mm

Processing methods: precision forging, CNC turning, surface treatment, etc.

Quality inspection: ultrasonic flaw detection, hardness test, tensile test

1、 Fixture classification

Bending fixture: suitable for conducting bending tests on materials, including three-point bending fixtures, four-point bending fixtures, clamp fixtures, etc.

Stretch fixture: suitable for conducting tensile tests on materials, including sheet metal fixtures, circular fixtures, V-shaped fixtures, clamp fixtures, etc.

Compression fixture: suitable for conducting compression tests on materials, including flat fixtures, spherical fixtures, cylindrical fixtures, etc.

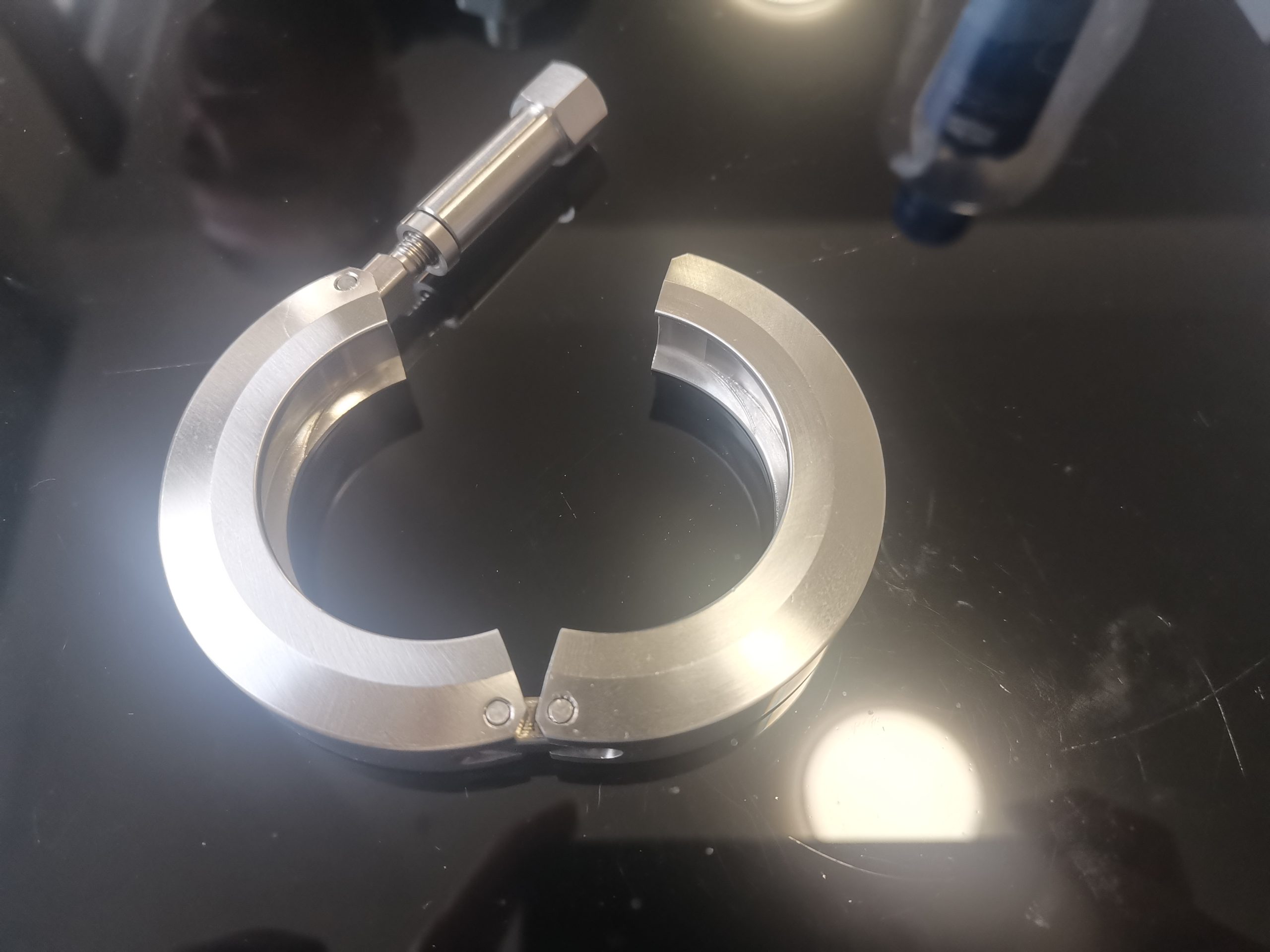

Shear fixture: suitable for conducting shear tests on materials, including direct shear fixtures, ring shear fixtures, etc.

2、 Fixture function

The function of the fixture is to fix the tested material, ensuring that it does not move or become unstable during the testing process, thereby ensuring the accuracy of the test results. The quality and performance of fixtures directly affect the reliability and accuracy of test results.

3、 Installation of fixtures

The installation of fixtures should be based on the specific type of fixture, but generally the following basic requirements need to be met:

Choose the appropriate fixture: Select the appropriate fixture based on the characteristics of the tested material and testing requirements.

Installation in place: Fix the fixture onto the testing machine and adjust the clamping force to ensure the stability and reliability of the fixture.

Check the fixture: Before conducting the test, the fixture should be inspected to ensure that there are no deformation, cracks, wear or other issues with the fixture.

4、 Maintenance of fixtures

The maintenance of fixtures mainly includes the following aspects:

Regular cleaning: The fixture should be cleaned regularly to prevent dust and impurities from damaging the surface of the fixture.

Applying lubricant: During the use of the fixture, lubricant should be applied regularly to reduce friction and wear of the fixture.

Check for wear: Regularly check the wear of fixtures, and replace or repair severely worn fixtures in a timely manner.

Keep dry: The fixture should be stored in a dry environment to avoid rust and corrosion.

Attention to protection: When using fixtures, attention should be paid to protection to avoid collisions or falls between fixtures and hard or other objects, in order to avoid damage to the fixtures.

5、 Fixture maintenance

Fixtures may encounter various problems during long-term use, such as wear, deformation, fracture, etc., and require timely maintenance or replacement. The specific maintenance methods are as follows:

Wear parts: For the wear parts of the fixture, grinding or spraying can be used to repair them.

Deformation and fracture: For the deformation and fracture of the fixture, it is necessary to replace the corresponding parts or replace the fixture as a whole.

Lubrication system: If the lubrication system of the fixture malfunctions, it needs to be cleaned or replaced.

Check clamping force: Regularly check whether the clamping force of the fixture is normal. If the clamping force is insufficient, the clamp can be adjusted or replaced.

In summary, the universal testing machine fixture plays a crucial role in the testing process, so it is necessary to select the appropriate fixture type and strictly follow the installation, maintenance, and repair requirements for operation to ensure the accuracy and reliability of the test results.

Types of metal clamps

1. Spiral clamps

Spiral clamps are a common metal clamp, which is made of a steel wire or aluminum wire bent in a spiral shape. Spiral clamps are easy to use and suitable for fixing various pipes and mechanical equipment.

2. Flat clamps

The structure of the flat clamp is a whole piece of metal plate, which is made by extrusion and bending. Compared with other types of metal clamps, flat clamps are more solid, so they are often used for piping and cable fixing of electrical equipment.

3. Spring clamps

The structure of the spring clamp is a spring steel wire, which is bent at both ends to form a clamp. The spring clamp has the characteristics of good elasticity and long life, and is suitable for fixing various mechanical equipment.

4. Pipe clamps

The structure of the pipe clamp clamp is two bent steel sheets. The pipe clamp clamp has the characteristics of good corrosion resistance and strong pressure bearing capacity, and is widely used in water heating, air conditioning and other fields.

Clamps can be divided into the following categories according to materials:

1. Stainless steel double wire clamps;

2. Carbon steel double wire clamps;

3. Phosphor bronze double wire clamps;

4. Galvanized double wire clamps;

5. Nickel-plated double wire clamps.

For the application of metal clamps in the automotive industry, the main ones involved are the engine’s intake pipe interface, exhaust pipe interface, and cooling inlet and outlet water pipe interface. Therefore, both gasoline engines and diesel engines are involved.

1. For passenger cars, gasoline engines are the main ones

Intercooler intake connection, cooling water pipe connection, turbocharger end connection, exhaust system connection, gasoline pipeline connection

2. For commercial vehicles. Mainly diesel engines

Intercooler intake connection, cooling water pipe connection, turbocharger end connection, exhaust system connection, gasoline pipeline connection, DPF system connection

Locking clamp usually refers to a mechanical component used to fix and clamp pipelines or pipelines to ensure that the pipeline system does not become loose or leak during operation. In different industrial and mechanical fields, locking clamps play an important role, especially in situations where high sealing performance, pressure resistance, and corrosion resistance are required. The locking clamp generally consists of two parts: one is the metal body, and the other is the fastening device. The metal body is used to fix on the pipe, while the fastening device locks the clamp by rotating or stretching to achieve the purpose of fixing the pipe. There are various types of locking clamps, and their designs vary according to different usage environments and requirements. For example, some are used for small diameter pipelines, while others are used for large diameter thick walled pipelines; There are fixed bolt type and snap type; There are also special material clamps used in high-pressure and high-temperature environments. When selecting and using locking clamps, the following factors usually need to be considered:

1. Size and material of the pipeline: Ensure that the size of the clamp matches the pipeline, and the material should adapt to the material and environment of the pipeline.

2. Working pressure and temperature: Select suitable clamps based on the pressure and temperature of the fluid inside the pipeline.

3. Sealing performance: Ensure that the clamp can provide good sealing effect and prevent fluid leakage.

4. Convenience of operation: Choose the type of clamp that is easy to operate according to installation and maintenance needs. Locking clamps are widely used in industries such as petroleum, chemical, water supply and drainage, fire protection, shipbuilding, and automotive. The correct selection and use of locking clamps are crucial for ensuring the safe operation of pipeline systems.

Contact Information for Clamp Locking Device Inquiries

For more information about Clamp Locking Device or to obtain customized solutions, please contact us:

- Contact Person: Frank

- Tel: 86-510-82305188-8060

- Mobile: 86-18605101203

- Mail: frankgu@cmecwuxi.com

- Address: 15-16F, Building A10, No. 777, JianZhu West Road, Binhu District, Wuxi, Jiangsu, 214072. P.R. China

We look forward to collaborating with you and providing robust support and services for your business.