Product Details

Our Heat Exchanger is widely and deeply used in many fields such as chemical processing, power generation and HVAC systems due to its high heat transfer efficiency, strong durability, energy saving and environmental protection and many other excellent product qualities; our Heat Exchanger has helped customers achieve many improvements such as improving heat exchange efficiency, reducing maintenance frequency and reducing energy consumption, helping them improve the operating efficiency of products and projects, improve the yield rate and reduce operating costs. In order to achieve these changes, our company has improved and optimized the material quality, manufacturing process and surface treatment of Heat Exchanger through long-term product research and technology improvement; at the same time, we will also regularly communicate with customers on technical needs, market feedback and product improvement suggestions to obtain the latest market needs and current market pain points, so as to improve our customized product processing capabilities.

Product specifications

Material: high-strength stainless steel, titanium alloy, aluminum alloy, etc.

Surface coating types: anti-corrosion coating, anodizing, coating protection, etc.

Tolerance range: ±0.01mm

Processing methods: precision forging, CNC turning, CNC milling, etc.

Quality inspection: ultrasonic flaw detection, pressure testing, three-coordinate measuring instrument

Product unique selling points

Selling point 1: In view of the low heat exchange efficiency problem in the current chemical processing industry, our company has made targeted adjustments to the Heat Exchanger. Our company has innovated the structural design of the Heat Exchanger and innovatively solved the problem of low heat exchange efficiency.

Selling point 2: In view of the equipment durability problem in the current power production industry, our company has made targeted adjustments to the Heat Exchanger. Our company has innovated the material selection of the Heat Exchanger and innovatively solved the equipment durability problem.

Selling point 3: In view of the energy consumption problem of the current HVAC system, our company has made targeted adjustments to the Heat Exchanger. Our company has innovated the energy-saving design of the Heat Exchanger and innovatively solved the energy consumption problem.

Selling point 4: In response to the corrosion problem in the current food processing industry, our company has made targeted adjustments to Heat Exchanger. Our company has innovated the anti-corrosion performance of Heat Exchanger and innovatively solved the corrosion problem.

Product application industry

Chemical processing: In the heat exchange project of the chemical processing industry, we found the problem of low heat exchange efficiency during market research. This problem seriously affected the production efficiency, maintenance cost and product quality of customers. Therefore, our company made targeted adjustments to the Heat Exchanger product. In related projects such as high heat transfer efficiency, strong durability and energy saving and environmental protection, our customers used our products, thereby improving production efficiency, reducing maintenance costs and improving product quality.

Power generation: In the heat exchange project of the power generation industry, we found the problem of equipment durability during market research. This problem seriously affected the operating stability, maintenance frequency and energy efficiency of customers’ equipment. Therefore, our company made targeted adjustments to the Heat Exchanger product. In related projects such as high-strength material selection, precision manufacturing and energy saving and environmental protection, our customers used our products, thereby improving the operating stability of equipment, reducing maintenance frequency and improving energy efficiency.

HVAC system: In the heat exchange project of HVAC system, we found the problem of energy consumption during market research, which seriously affected the customer’s operating cost, system efficiency and environmental impact. Therefore, our company made targeted adjustments to the Heat Exchanger product. In related projects such as high heat transfer efficiency, energy-saving design and durable protection, our customers used our products, which reduced operating costs, improved system efficiency and reduced environmental impact.

Food processing: In the heat exchange project of the food processing industry, we found the problem of corrosion during market research, which seriously affected the customer’s equipment life, maintenance cost and product safety. Therefore, our company made targeted adjustments to the Heat Exchanger product. In related projects such as high heat transfer efficiency, anti-corrosion performance and strong durability, our customers used our products, which improved equipment life, reduced maintenance costs and improved product safety.

As a heat transfer device that transfers part of the heat of the hot fluid between materials to the cold fluid, the heat exchanger is widely used in people’s daily life and in industries such as petroleum, chemical, power, medicine, atomic energy and nuclear industry. It can be used as an independent device, such as a heater, condenser, cooler, etc.; it can also be used as a component of certain process equipment, such as a heat exchanger in some chemical equipment.

Especially in the chemical industry with high energy consumption, heat exchangers are indispensable equipment in the heat exchange and transfer process of chemical production, and they also account for a considerable proportion of the entire chemical production equipment.

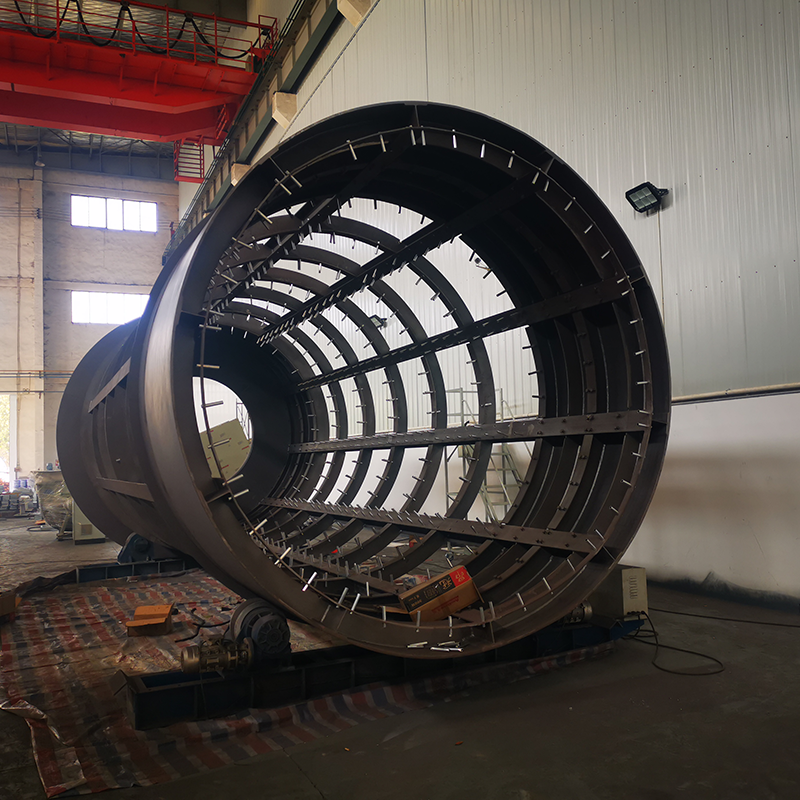

From the perspective of its function, the heat exchanger is, on the one hand, to ensure the specific temperature required by the industrial process for the medium, and on the other hand, it is also the main equipment to improve energy utilization. According to its structural form, there are mainly plate heat exchangers, floating head heat exchangers, fixed tube plate heat exchangers and U-tube heat exchangers, etc. Among them, except for plate heat exchangers, the other types belong to shell and tube heat exchangers.

Since the shell and tube heat exchanger has a large heat exchange area per unit volume, good heat exchange effect, strong structure, strong adaptability, mature manufacturing process and other advantages, it has become the most commonly used typical heat exchanger.

Connection between heat exchange tubes and tube sheets in shell and tube heat exchangers

In shell and tube heat exchangers, heat exchange tubes and tube sheets are the only barrier between the tube side and shell side of the heat exchanger. The connection structure and connection quality between the heat exchange tubes and tube sheets determine the quality and service life of the heat exchanger, which is a crucial link in the manufacturing process of the heat exchanger.

Most of the damage and failure of heat exchangers occur at the connection between the heat exchange tubes and tube sheets. The quality of the connection joints also directly affects the safety and reliability of chemical equipment and devices. Therefore, the connection process between the heat exchange tubes and tube sheets in shell and tube heat exchangers has become the most critical control link in the quality assurance system of heat exchanger manufacturing. At present, in the manufacturing process of heat exchangers, the connection between heat exchange tubes and tube sheets mainly includes: welding, expansion, expansion plus welding, and adhesive plus expansion.

1. Welding

When the heat exchange tube and the tube sheet are connected by welding, the processing requirements for the tube sheet are low, the manufacturing process is simple, the sealing is good, and welding, appearance inspection, and maintenance are very convenient. It is currently the most widely used connection method for the heat exchange tube and tube sheet in the shell and tube heat exchanger. When welding is used, there are strength welding that guarantees the sealing and pull-off strength of the welding joint and sealing welding that only guarantees the sealing of the connection between the heat exchange tube and the tube sheet. The performance of strength welding is limited and is only suitable for occasions with small vibration and no gap corrosion.

When welding is used, the distance between the heat exchange tubes cannot be too close, otherwise it will be affected by heat and the quality of the weld will not be easy to guarantee. At the same time, a certain distance should be left at the tube ends to reduce the welding stress between each other. The length of the heat exchange tube extending out of the tube sheet must meet the specified requirements to ensure its effective load-bearing capacity. In terms of welding methods, welding can be carried out by arc welding, TIG welding, CO2 welding, etc. according to the material of the heat exchange tube and the tube sheet. TIG welding is suitable for heat exchangers with high connection requirements between heat exchange tubes and tube sheets, such as heat exchangers with high design pressure, high design temperature, large temperature changes, and heat exchangers with alternating loads, thin tube sheet heat exchangers, etc.

Conventional welding connection methods are prone to gap corrosion and overheating due to the gap between the tube and the tube sheet hole, and the thermal stress generated at the welded joint may also cause stress corrosion and damage, all of which will cause the heat exchanger to fail. At present, in heat exchangers used in domestic nuclear industry, power industry and other industries, the connection between heat exchange tubes and tube sheets has begun to use internal hole welding technology. This connection method changes the end welding of heat exchange tubes and tube sheets to the inner hole welding of tube bundles, adopts full penetration form, eliminates the gap of end welds, and improves the ability to resist gap corrosion and stress corrosion.

It has high vibration fatigue resistance, can withstand high temperature and high pressure, and has good mechanical properties of welded joints; the joints can be subjected to internal non-destructive testing, the internal quality of the weld can be controlled, and the reliability of the weld is improved. However, the inner hole welding technology is difficult to assemble, has high requirements for welding technology, is complex to manufacture and inspect, and has relatively high manufacturing costs. As heat exchangers develop towards high temperature, high pressure and large-scale, the requirements for their manufacturing quality are getting higher and higher, and the inner hole welding technology will be more widely used.

2. Expansion

Expansion is a traditional method of connecting heat exchange tubes and tube sheets. It uses an expansion device to make the tube sheet and the tube produce elastic-plastic deformation and fit tightly to form a firm connection, achieving the purpose of sealing and resisting pull-off. In the manufacturing process of heat exchangers, expansion is suitable for occasions without severe vibration, excessive temperature changes, and severe stress corrosion.

The expansion processes currently used are mainly mechanical rolling expansion and hydraulic expansion. Mechanical rolling expansion is uneven, and once the connection between the tube and the tube sheet fails, it is very difficult to repair it with expansion tubes; the liquid bag hydraulic expansion is controlled by a computer, with high precision, and can ensure that the tightness of the expansion is uniform and consistent, and the reliability of the connection is better than that of mechanical expansion. However, it has strict requirements on processing accuracy, and it is also difficult to ensure the success of expansion for dense joints. If it fails, it is also difficult to repair it by expansion.

3. Expansion plus welding

When the temperature and pressure are high, and under the action of thermal deformation, thermal shock, thermal corrosion and fluid pressure, the connection between the heat exchange tube and the tube sheet is very easy to be damaged. It is difficult to ensure the connection strength and sealing requirements by expansion or welding. At present, the method of expansion and welding is widely used. The expansion plus welding structure can effectively damp the damage to the weld caused by the vibration of the tube bundle, effectively eliminate stress corrosion and gap corrosion, and improve the fatigue resistance of the joint, thereby increasing the service life of the heat exchanger. It has higher strength and sealing than simple expansion or strength welding. For ordinary heat exchangers, the form of “sticking expansion + strength welding” is usually adopted; while heat exchangers with harsh operating conditions require the form of “strength expansion + sealing welding”. Expansion plus welding can be divided into two types according to the order of expansion and welding in the process: expansion first and then welding and welding first and then expansion.

(1) Expansion first and then welding The lubricating oil used in expansion will penetrate into the joint gap, and they are very sensitive to welding cracks, pores, etc., which makes the phenomenon of defects during welding more serious. The oil and dirt that penetrate into the gap is difficult to clean, so the expansion-before-welding process is adopted, and the mechanical expansion method is not suitable. Although the expansion method is not pressure-resistant, it can eliminate the gap between the tube and the tube plate hole, so it can effectively damp the vibration of the tube bundle to the welding part of the tube mouth.

However, the conventional manual or mechanically controlled expansion method cannot achieve the uniform expansion requirement, while the liquid bag expansion method with computer-controlled expansion pressure can conveniently and evenly achieve the expansion requirement. During welding, due to the influence of high-temperature molten metal, the gas in the gap is heated and expands rapidly. These high-temperature and high-pressure gases will cause certain damage to the sealing performance of the strength expansion when leaking.

(2) Welding first and then expanding For the welding-before-expansion process, the primary problem is to control the accuracy and coordination of the tube and the tube plate hole. When the gap between the tube and the tube plate hole is small to a certain value, the expansion process will not damage the quality of the welded joint. However, the ability of the weld to withstand shear force is relatively poor, so during strength welding, if the control does not meet the requirements, it may cause over-expansion failure or damage to the welded joint due to expansion.

During the manufacturing process, there is a large gap between the outer diameter of the heat exchange tube and the tube hole of the tube sheet, and the gap between the outer diameter of each heat exchange tube and the tube hole of the tube sheet is uneven along the axial direction. When the expansion joint is completed after welding, the center line of the tube must coincide with the center line of the tube hole of the tube sheet to ensure the quality of the joint. If the gap is large, due to the large rigidity of the tube, excessive expansion deformation will damage the welded joint and even cause the weld to desolder.

4. Gluing and expansion joint

The use of glue and expansion joints helps to solve the leakage and seepage problems that often occur at the connection between the heat exchange tube and the tube sheet in the heat exchanger. It is important to correctly select the adhesive according to the working conditions of the glued parts. During the implementation of the process, the process parameters should be selected in combination with the structure and size of the heat exchanger, mainly including curing pressure, curing temperature, expansion force, etc., and strictly controlled during the production process. This process is simple, easy and reliable. It has been recognized in the actual use of enterprises and has promotion value.

Customer Case

Customer Background

The company that this product has served is a chemical equipment company in the chemical processing industry in Germany. The company is in the chemical processing industry, and its main products are reactors, separation equipment and heat exchangers. It has 800 employees and annual sales of 100 million euros.

Problems faced by customers

The main challenges currently faced by this company are low heat exchange efficiency, poor equipment durability and high energy consumption. This problem has led to frequent equipment failures, high maintenance costs and low production efficiency in the company’s current business status, which has caused many chain reactions, such as declining customer satisfaction, reduced orders and weakened market competitiveness.

Solution

Based on the above three actual problems of this customer, our Heat Exchanger has carried out inspections and analysis and technical adjustments on the structural design, material selection and surface treatment of the Heat Exchanger, and has made targeted customized adjustments to the heat transfer efficiency, durability and corrosion resistance of the Heat Exchanger, providing innovative solutions to solve the low heat exchange efficiency, poor equipment durability and high energy consumption.

Product Effect

In the actual project operation of customers, our Heat Exchanger has indeed helped customers improve heat exchange efficiency, equipment durability and energy utilization, and reduced equipment failure rate, maintenance costs and production energy consumption. These have helped customers achieve a 30% increase in heat exchange efficiency, a 25% reduction in equipment failure rate and a 20% reduction in energy consumption during project execution.

Contact Information for Heat Exchanger Inquiries

For more information about Heat Exchanger or to obtain customized solutions, please contact us:

- Contact Person: Frank

- Tel: 86-510-82305188-8060

- Mobile: 86-18605101203

- Mail: frankgu@cmecwuxi.com

- Address: 15-16F, Building A10, No. 777, JianZhu West Road, Binhu District, Wuxi, Jiangsu, 214072. P.R. China

We look forward to collaborating with you and providing robust support and services for your business.