Product Details

A flange is a component that connects shafts and is used for connecting pipe ends; Also useful are flanges on the inlet and outlet of equipment, used for connecting two devices, such as gearbox flanges. A flange connection or flange joint refers to a detachable connection formed by a combination of flanges, gaskets, and bolts connected together as a sealing structure. Pipeline flange refers to the flange used for piping in pipeline equipment, and when used on equipment, it refers to the inlet and outlet flanges of the equipment. There are holes on the flange, and bolts make the two flanges tightly connected. Seal the flanges with gaskets. The flange is divided into threaded connection (threaded connection) flange, welded flange, and clamp flange. The flanges are used in pairs, and threaded flanges can be used for low-pressure pipelines, while welded flanges are used for pressures above four kilograms. Add a sealing gasket between the two flanges and tighten them with bolts. The thickness of flanges under different pressures varies, and the bolts used are also different. When connecting water pumps and valves to pipelines, the local parts of these equipment are also made into corresponding flange shapes, also known as flange connections. Any connecting part that is closed and connected by bolts around two planes is generally referred to as a “flange”, such as the connection of ventilation ducts. This type of part can be called a “flange type part”. But this connection is only a partial part of the equipment, such as the connection between the flange and the water pump, so it is not easy to call the water pump a “flange type part”. Smaller components such as valves can be called “flange parts”.

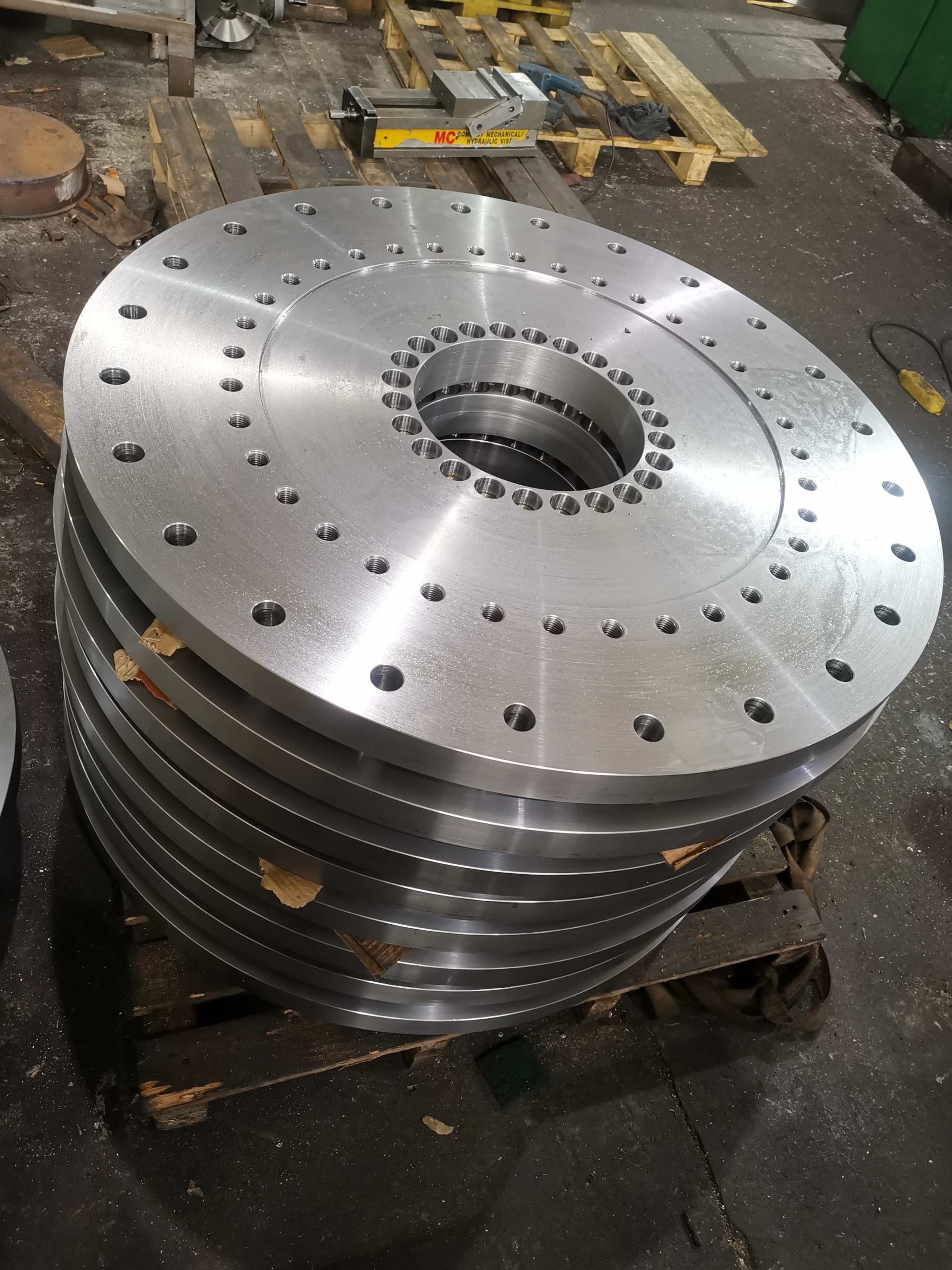

Reducer flange, used for connecting the motor to the reducer, as well as connecting the reducer to other equipment.

Flange production process

As a connecting and sealing component, flanges will leak if there are quality problems during the production process, causing economic losses, environmental damage and even safety accidents, so flange welding and production are very important.

At present, there are two main production processes for flanges: forging and casting. Let’s take a look at these two main production processes and see what the differences are.

Forged flange

Forged flanges are made by hammering the forging machine countless times to make the internal structure of the steel become tight, so the mechanical properties will be better and the strength will be high. The forged flanges are mainly suitable for pipes with high pressure.

First, the cylindrical steel billet is cut according to a certain size, heated to a certain temperature to make it thermoplastic, and placed on the cold forging to let the forging machine continuously hammer the steel billet, so that the inside of the steel billet is tighter and the mechanical properties are better than the original steel billet.

The round hole on the flange is also punched out on the steel billet by a stamping machine. The formed blank flange is placed in an electric furnace for heat treatment to increase the strength of the flange. Finally, the flange blank is cut and polished to become a usable flange.

Casting flange

Casting flange has the characteristics of low manufacturing cost and high efficiency. It can produce flanges with complex shapes. The cast flanges are mainly suitable for pipes with low pressure.

Casting flange is also a commonly used manufacturing process. It melts the metal into liquid steel and pours the steel into a preheated and constant temperature metal mold to form the shape of the flange. After the casting is naturally cooled and formed within a period of time, it is quickly cooled and demolded with water, which can also increase the strength of the flange. Finally, it can be used after polishing and rust prevention.

The basic sealing surfaces of flanges include:

Full plane FF

RF protrusion

Concave FM

Convex surface M

Tenon surface T

Slot surface G

There are five types of ring connection surfaces, including RTJ (RJ), which are selected according to different working conditions, media, pressure, specifications, temperature, etc.

FF – Full plane

The sealing surface of the Flat Face Full Face type is fully flat, suitable for situations with low pressure and non-toxic media.

RF protrusion surface

Raised Face type sealing surfaces are the most widely used and commonly used among several types. International standards, European systems, and domestic standards all have a fixed height. However, in American standard flanges, it should be noted that high pressure heights will increase the height of the sealing surface, and there are also various types of gaskets used. There are various non-metallic flat gaskets and wrapped gaskets suitable for flange with raised sealing surfaces; Metal wrap cushion; Spiral wound gaskets (including those with outer rings or inner and outer rings), etc.

M-convex surface

FM – Concave surface

The two types of sealing surfaces, Male Face and Female Face, are a pair, one female and one male, and must be used together for easy alignment during assembly and to prevent the gasket from being squeezed out. Suitable for high pressure situations.

The sealing gaskets suitable for concave convex sealing surfaces include various non-metallic flat gaskets and wrapping gaskets; Metal wrap cushion; Basic type or inner ring type winding film, etc.

T-tenon surface

G-groove surface

Tongue Face and Groove Face are similar in terms of concave and convex surfaces, and are also paired with a male and female sealing surface type, both used in pairs. The gasket is located in a circular groove and is limited by the metal walls on both sides, which can prevent the gasket from being squeezed into the pipeline due to compression deformation. Due to the fact that the gasket does not come into direct contact with the fluid medium inside the pipe, it is less susceptible to erosion or corrosion by the fluid medium. Therefore, it can be used in high-pressure, flammable and explosive, toxic media, and other situations that require strict sealing requirements. This type of sealing gasket has good installation accuracy, but it is difficult to process the sealing surface. When replacing the gasket, it is easy to damage the sealing surface, and the flange must be separated axially during installation and disassembly. Therefore, in pipeline design, the possibility of separating the flange axially should be considered.

The gaskets suitable for sealing surfaces of tenon and groove surfaces include various metal and non-metal flat gaskets, metal wrapped gaskets, and basic spiral wound gaskets.

RTJ (RJ) – Ring Connection Surface

The flange for ring joint face sealing also belongs to narrow face flange, and a circular trapezoidal groove is opened on the protruding surface of the flange as the flange sealing surface. Like the tenon groove face flange, this type of flange must be separated axially during installation and disassembly. Therefore, in pipeline design, the possibility of separating the flange axially should be considered.

This sealing surface is specifically designed to match solid metal gaskets processed into octagonal or elliptical shapes with metal materials, achieving sealing connections. Due to the inherent characteristics of various metals, the metal ring gasket has good sealing performance and less strict installation requirements, making it suitable for high temperature and high pressure working conditions. However, the machining accuracy of the sealing surface is relatively high.

1、 What is a looping flange, where is a looping flange used, and in what fittings?

A looping flange is a movable flange that is usually matched with drainage fittings (most commonly on expansion joints). When the manufacturer leaves the factory, there is a flange at each end of the expansion joint, which is directly connected to pipelines and equipment in the project with bolts.

2、 How is the flange connected to the pipeline and where is it welded?

There are many classifications of flanges. Generally used are flat flanges, butt welding flanges (long neck flanges), looped flanges, etc. Flat welding flanges are used for medium and low pressure, using plug welding and welding on both sides. The welding depth is 2-5mm from the sealing surface of the flange. The butt welding flange can be directly welded, and the bolted connection of the loop flange does not require welding.

3、 What does flange mean?

A flange is a connector used to connect a valve to a pipeline. When a valve is connected to a pipeline, the connection is made through bolts. Therefore, the two end faces of the valve with N evenly distributed bolt holes are considered flange type.

1. “Flange” is the transliteration of “flange”, meaning something or part with a flange. This type of part can be individual, such as a flange, or a combination type, such as a pipe with a flange at one or both ends. The flange has several through holes for installing screws, and some bearings have a flange on the outer ring. This flange can have holes or not, and is only used for edge positioning.

2. Flange type: The connection between the valve and the pipeline or machine equipment adopts flange connection, which is commonly referred to as flange type.

4、 What is a flange?

A flange is a disc-shaped component that is most common in pipeline engineering, and flanges are used in pairs. In pipeline engineering, flanges are mainly used for connecting pipelines. Install a flange plate on the pipeline that needs to be connected. For low-pressure pipelines, threaded flanges can be used, and for pressures above 4 kilograms, welded flanges can be used. Add sealing points between the two flanges and tighten them with bolts. Different flanges with different pressures have different thicknesses and use different bolts. When connecting water pumps and valves to pipelines, the local parts of these equipment are also made into corresponding flange shapes, also known as flange connections. Any connecting parts that are closed and bolted together in two planes are generally referred to as “flanges”, such as the connection of ventilation ducts. This type of part can be referred to as “flange type parts”. But this connection is only a partial part of the equipment, such as the connection between the flange and the water pump, so it is not easy to call the water pump a “flange type part”. Smaller components such as valves can be called “flange parts”.

5、 What is the connection method for flanges?

Flange connection is an important connection method in pipeline construction.

A flange connection is the process of fixing two pipes, fittings, or equipment onto a flange. A flange gasket is added between the two flanges, and bolts are used to secure them together to complete the connection. Some pipe fittings and equipment already come with flanges, which also belong to flange connections.

The flange is divided into threaded connection (threaded connection) flange and welded flange. Low pressure small diameter threaded flanges are used, while high pressure and low pressure large diameter flanges use welded flanges. The thickness of the flange plate and the diameter and number of connecting bolts vary for different pressures.

According to different levels of pressure, flange gaskets also have different materials, from low-pressure asbestos gaskets, high-pressure asbestos gaskets to metal gaskets.

The flange connection is convenient to use and can withstand large pressures.

In industrial pipelines, flange connections are widely used. In households, the diameter of the pipeline is small and it is low-pressure, so flange connections are not visible. If in a boiler room or production site, there are pipes and equipment connected by flanges everywhere. A flange connection is the process of fixing two pipes, fittings, or equipment onto a flange. A flange gasket is added between the two flanges, and bolts are used to secure them together to complete the connection. Some pipe fittings and equipment already come with flanges, which also belong to flange connections.

Pay attention when connecting, especially when tightening bolts, to ensure that all bolts are tightened equally.

6、 What is the use of flanges?

The flange is used for positioning.

For example, there is an installation method for oil cylinders called flange installation, which is to drill four symmetrical holes around a rectangular prism, with a large hole in the middle that is the same as the outer diameter of the oil cylinder. The rectangular prism can be placed on the oil cylinder and welded together in other ways. The oil cylinder and other things are connected by the four holes around the rectangular prism, which can be called a flange.

7、 What is the difference between the connection method of orifice flange and ordinary flange?

It is to fix two pipes, fittings or equipment on a flange, add flange pads between the two flanges, and tighten them together with bolts to complete the connection.

The orifice plate flange is a type of orifice plate flowmeter that connects the orifice plate (the measuring part of the orifice plate flowmeter) to the pipeline. The two flanges fix the orifice plate in the middle and guide it to the differential pressure transmitter through the pressure tapping point on the flange to measure the flow rate.

8、 What issues should be noted during installation to ensure that the installed flange does not leak oil?

1. The flange should have sufficient strength and should not deform during tightening. The flange sealing surface should be flat and clean, and oil stains and rust spots should be carefully cleaned during installation.

2. The sealing gasket shall have good oil resistance and aging resistance, as well as good elasticity and mechanical strength. Installation should select sealing gaskets with different cross-sections and sizes according to the shape of the connection, and place them correctly.

3. The flange tightening force should be uniform and consistent, and the compression amount of the gasket should be controlled at 1/3.

9、 What is the difference between butt welded flanges and flat welded flanges?

A butt welding flange is a pipe with the same diameter and wall thickness as the pipe to be welded at the interface end, which is welded together as two pipes.

Flat welding flange is a concave platform machined at the interface that is slightly larger than the outer diameter of the pipe, and the pipe is inserted and welded inside.

The welding performance of butt welding is relatively good, and the corrosion is relatively small.

Flat welding and butt welding are the welding methods used for connecting flanges and pipelines. Flat welding only requires single-sided welding without welding the inner opening of the pipeline and flange connection. The welding installation of butt welding flanges requires double-sided welding of the flange. So flat welding flanges are generally used for low and medium pressure pipelines, while butt welding flanges are used for connecting medium and high pressure pipelines. The flange for butt welding is generally at least PN2.5MPa, and the use of butt welding is to reduce stress concentration. Generally, butt welding flanges are mostly neck flanges, also known as nipple flanges. So the installation cost, labor cost, and auxiliary material cost for welding flanges should be higher because there is an additional process.

Not all butt welding flanges require double-sided welding both inside and outside. If there are no special requirements, it is usually only welded on the outside. Have you never seen a 1/2 “butt welding flange? Flat welding is easier to weld because the pipe and flange are perpendicular and the pipe will not be inclined.

10、 What is the difference between flanges and valves?

A valve is something like a faucet, or in other words, a faucet is a type of valve. It can be twisted open, and water or gas can flow out; It can be closed, and the water won’t flow.

The tap at home is threaded onto the pipe, but some pipes used in the factory have high pressure for water or gas inside, and the threaded connection is not strong enough. Therefore, they can be directly welded or connected by other methods. Flange is one of the connection methods.

11、 Example of flange marking and marking

1. National standard marking: flanges should be marked according to the nominal diameter, nominal pressure, sealing surface form code, steel pipe series code used (with metric pipe code “Series 2” and British pipe code not marked) and standard number.

Marking example: Raised face welded steel pipe flange with a nominal diameter of 80mm and a nominal pressure of 4.0MPa (25bar) (equipped with metric pipes)

Flange DN80-PN40 M (Series 2) GB/T9115.2-2000, raised face flat welded steel pipe flange with a nominal diameter of 100mm and a nominal pressure of 5.0MPa (25bar) (equipped with British pipes), flange DN100-PN50 RF GB/T9116.1-2000.

2. Mechanical Department Standard Markings:

Marking example: Raised face flat welded steel pipe flanges with a nominal diameter of 500mm and a nominal pressure of 1.6MPa, Series 2

Flange 500-16 JB/T81-94

Concave butt welded steel pipe flanges with a nominal diameter of 300mm and a nominal pressure of 6.4MPa, Series 1

Flange 300-64B (Series 1) JB/T82.2-94

(Note: The default outer diameter of pipes in the mechanical department standard is Series 2, and the classification of welding flanges is: A-type convex surface, B-type concave surface, C-type tenon surface, D-type groove surface)

3. Standard marking of the Ministry of Chemical Industry: flanges should be marked according to the following regulations (this marking method is recommended)

a、 Standard number: All types of pipe flanges are uniformly marked with the standard number of this standard: HG20592.

b、 The flange type code shall be in accordance with the provisions of Table 5.0.1.

When threaded flanges use tapered pipe threads according to GB/T7306, they are marked as “Th (Rc)” or “Th (Rp)”;

When using tapered pipe threads according to GB/T12716 for threaded flanges, it is marked as “Th (NPT)”;

If the thread code is not marked on the threaded flange, it is Rp (GB/T7306.1).

c、 Flange nominal diameter DN (mm) and applicable steel pipe outer diameter series:

Integral flange, flange cover, lined flange cover, threaded flange, and the markings applicable to the outer diameter series of steel pipes can be omitted;

Suitable for flanges of international standard series steel pipes (commonly known as British pipes), marked with “DN (A)”;

Suitable for flanges of domestic series steel pipes (commonly known as metric pipes), marked as “DN (B)”.

d、 The nominal pressure of the flange is PN, MPa.

e、 The form code of the sealing surface shall be in accordance with the provisions of Table 6.0.1. If the raised face flange is machined with a dense water line, it shall be marked as “RF (A)”.

f、 The wall thickness of the steel pipe should be provided by the user.

The wall thickness of the steel pipe should be marked on the neck welding flange and the loose sleeve flange of the welding ring.

g、 Material grade.

h、 Other. Adopt requirements or additional requirements that are inconsistent with the provisions of this standard series, such as the surface roughness of the sealing surface.

Contact Information for Flange Inquiries

For more information about flange or to obtain customized solutions, please contact us:

- Contact Person: Frank

- Tel: 86-510-82305188-8060

- Mobile: 86-18605101203

- Mail: frankgu@cmecwuxi.com

- Address: 15-16F, Building A10, No. 777, JianZhu West Road, Binhu District, Wuxi, Jiangsu, 214072. P.R. China

We look forward to collaborating with you and providing robust support and services for your business.