Product Specifications

Material: High-strength alloy steel

Surface coating type: Anti-corrosion coating

Tolerance range: ±0.02mm

Processing method: Precision forging and welding technology

Quality inspection: Ultrasonic flaw detection and load test

Components of marine cranes:

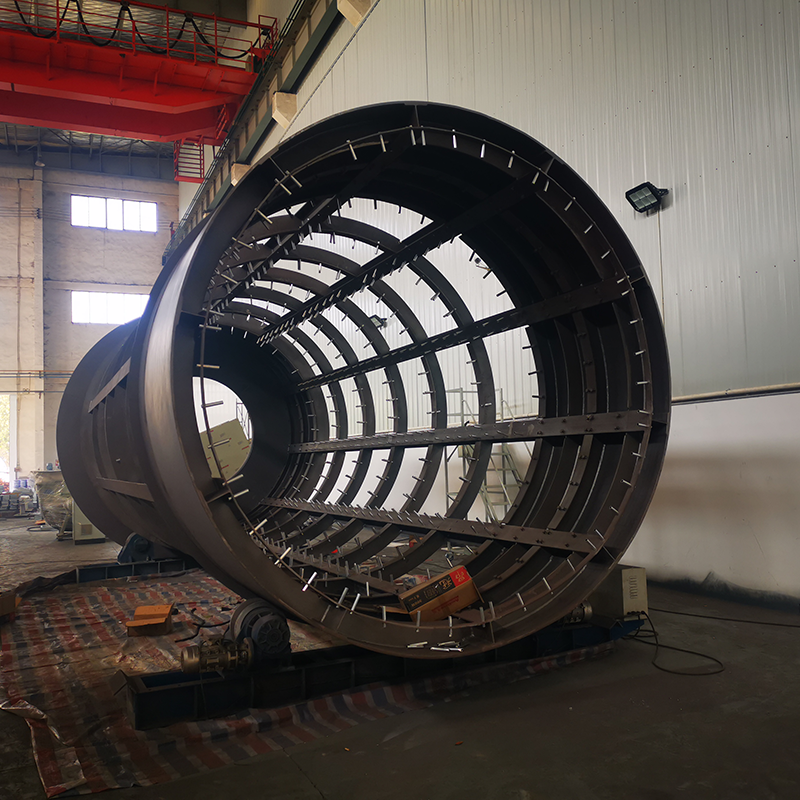

Marine cranes are currently used in bulk carriers, container ships, oil tankers, multi-purpose ships, and so on. Such as cargo cranes for bulk carriers and container ships, hose cranes for oil tankers, and deck cranes for multi-purpose ships. Compared to general land cranes, marine cranes, due to their installation on unstable ships, may experience tilting, swaying and other movements during operation, and their working environment is harsh and variable, requiring them to withstand erosion from sea winds, seawater, and other factors; When not working, it also needs to withstand external forces such as wind, snow, waves, sway, heave, and impact during ship navigation. There are various structural forms of marine cranes, such as boom rotary, walking, wire rope variable amplitude, oil cylinder variable amplitude, telescopic arm, folding arm, A-frame, composite, etc; The driving methods vary, including electric, electro-hydraulic, electro-pneumatic, gasoline (diesel) engine, and manual driving. The most typical is the electro-hydraulic crane installed on bulk carriers for cargo loading and unloading. The load-bearing structure of marine cranes, such as the foundation column, tower body, and boom, are welded structural components made of metal steel plates. The lower part of the foundation column is welded to the hull structure, bearing the gravity load of the crane, and the upper part of the foundation column is equipped with a rotating support; The tower body is the supporting structure of the crane, with the lower part connected to the slewing support and hinged with the boom. The upper part has a pulley group and steel wire rope for movement. The interior of the tower body is used as a computer room, and the driver’s cab is located in the front; The arm frame is a symmetrical truss structure used to support heavy objects.

The mechanisms of marine cranes include lifting mechanisms, variable amplitude mechanisms, rotating mechanisms, and other executive mechanisms. The lifting mechanism is driven by a motor through a reducer to rotate the drum and retract the steel wire rope, causing the hook to move up and down to lift the goods and carry out the lifting movement; The variable amplitude mechanism is driven by a motor through a reducer to rotate the drum and retract the steel wire rope, causing the boom to rotate up and down around the lower hinge point to change the angle and enable the hook to perform variable amplitude motion at different amplitudes; On the side of the rotating mechanism, there is a motor that drives the small gear through a reducer to mesh with the large gear of the rotating support, causing the tower body and arm frame to rotate and perform rotational motion; All three mechanism gearboxes are equipped with normally closed brakes to ensure the normal operation of their respective movements. Coordinate the operation of three institutions to lift the load to the required position within the scope of work.

The electrical system of the driving and control parts consists of various control components inside the electric control box, which are required to form a control system. They are operated and controlled through buttons and handles installed on the operation console on both sides of the driver’s seat. The hydraulic system consists of pumps, motors, valve groups, pipelines, and their accessories to control and drive the movement of several actuators. Marine cranes also have auxiliary devices such as channels and ventilation devices.

With the development of the offshore oil drilling platform industry, higher and higher requirements have been put forward for the installation and maintenance of large marine cranes, mainly manifested in the continuous improvement of basic functional parameters. The lifting capacity of a single machine is generally above 1000t, and the operating range can reach nearly 100 meters, reaching a lifting height of 2000 meters for underwater operations, and requiring the crane to be able to rotate fully. Higher requirements have also been put forward for the effective operating area of the deck of lifting vessels, and users often demand that the smaller the deck area occupied by marine cranes, the better. In addition, some users have requested to reduce the tail turning radius, set the driving mechanism inside the rotating column, and to reduce the external dimensions of the crane, it is not allowed to use the method of adding balance weights to reduce the overturning torque. In summary, the development of marine cranes used in marine engineering requires their performance to be increasingly superior and their forms to be more concise. These requirements pose a severe challenge to the design and manufacturing of crane slewing support devices. To meet these requirements, the slewing support is usually of the column type and installed below the ship deck. At present, the rotary column type slewing bearing is usually composed of a set of upper rollers and a bottom centripetal thrust bearing. The upper rollers bear the horizontal force generated by the overturning moment, while the bottom centripetal thrust bearing bears both horizontal and vertical forces. The lifting torque of a large tonnage fully rotating crane can reach over 100000 tons per meter. In this case, the horizontal and vertical forces of the slewing support are relatively large, and the load can reach over 3000 tons. To achieve load-bearing capacity, it is necessary to increase the diameter and number of rollers, which results in rollers occupying too much deck space and is unacceptable to users; In addition, the friction coefficient between the roller and the track is relatively high, resulting in an increase in rotational resistance and an increase in rotational driving power. For the bottom centripetal thrust bearing, it bears bidirectional loads of horizontal and vertical forces. In the existing forms of column type rotary bearings, this radial thrust bearing is also decomposed into a radial spherical bearing and a self-aligning thrust bearing. The two bearings bear horizontal and vertical forces respectively. To ensure automatic positioning, the centers of the two bearing spherical surfaces coincide at a point. Usually suitable for situations with small loads and dimensions, and accuracy can only be guaranteed through machining.

Classification of marine crane equipment:

The suspension rod device can be divided into two categories: light and heavy. Light suspension rod devices are used for lifting weights below 10 tons, and heavy suspension rod devices are used for lifting weights exceeding 10 tons. The lifting capacity of the boom is determined based on the purpose of the vessel. The lifting capacity of a light cargo ship’s single pole operation is 3-5 tons, and the double pole operation is 1.5-3 tons; The single pole operation lifting capacity of a 10000 ton dry cargo ship can reach 10 tons, and the double pole operation can reach 5 tons. Modern multi-purpose ships need to load and unload containers, and the lifting capacity of the boom should be able to lift at least 20 feet (20 tons) of containers. Heavy lifting rods are used for loading and unloading large machinery, locomotives, and other heavy goods. Generally, only 1-2 rods are installed on cargo ships, with a lifting capacity of mostly 10-60 tons, some 60-150 tons, and a few up to 300 tons. Generally, dry cargo ships have two light suspension rods in each cargo hold; Giant dry cargo ships often have four light suspension rods installed in each cargo hold.

Deck crane

Machinery installed on the deck of a ship. This type of crane has a compact structure, allowing the ship to have more deck area available for use and less impact on the line of sight above the bridge. The deck crane is easy to operate, with high loading and unloading efficiency, flexible mobility, and no tedious preparation work before operation, making it increasingly widely used.

The commonly used deck cranes include fixed rotating cranes, mobile rotating cranes, and gantry cranes. There are two types of transmission methods: electric transmission and electric hydraulic transmission.

Fixed rotating crane

This type of crane is the most widely used and can operate independently or in pairs on the starboard and starboard sides. The lifting capacity is generally 3-5 tons. On multi-purpose ships, it is required that a single crane can lift a 20 foot container and a double crane can lift a 40 foot container (30 tons), with a lifting capacity of 25-30 tons.

Mobile rotary crane

When loading and unloading goods, it is often necessary to use a mobile rotating crane when the crane span is large and the crane boom is not too long. There are two types of mobile rotary cranes: horizontal movement along the ship and vertical movement.

Gantry crane

This type of crane is widely used by container ships and barges, usually in the form of a quadruped or C-type. There is an extendable boom, a lifting crossbar, a movable bridge, and a cab. The horizontal main beam of the bridge is higher than the container stacked on the deck and has an automatic positioning device, which can accurately place the container in the container compartment or stack it on the deck during loading. There are more gantry cranes on the barge than on the container ship, with a lifting capacity of several hundred tons.

Other loading and unloading machinery

There are mainly elevators, hoists, and conveyors. An elevator is a mechanical device that moves vertically along a guide rail on a ship, used to lift and lower cargo between different decks. On roll on/roll off ships, elevators are often used to connect each deck for transporting goods. There are several types of elevators on roll on/roll off ships, including scissor type and chain type, with a length of 9-18.5 meters and a width of 3-5 meters. Some cargo barges are also equipped with elevators for loading and unloading cargo barges, but their lifting capacity is much larger than that on roll on/roll off ships. Elevators are used to continuously transport goods in the vertical or larger inclined direction. A conveyor continuously transports goods in a horizontal or slightly sloping direction. These two types of machinery are mostly used on self dumping ships or ships that load and unload through gangways.

How to choose a marine crane according to the type of ship

Common ship types include bulk carriers, large container ships, tankers, fishing boats and yachts. Each ship type has its own unique uses and special requirements. Therefore, when choosing a marine crane, we need to consider the following factors:

- Load capacity: Different types of ships can carry different weights of cargo. Therefore, when choosing a marine crane, you need to ensure that it can meet the weight requirements of the cargo on board. For example, cargo ships usually need to have a high load capacity in order to load a large amount of cargo.

- Working range: The working range of a marine crane is also an important consideration. Different types of ships may require different working ranges when loading and unloading cargo. For example, container ships usually need to have a large working range in order to load and unload cargo above the dock.

- Environmental adaptability: Marine cranes need to adapt to different environmental conditions, including marine environments and bad weather. Therefore, when choosing a marine crane, you need to ensure that it has good corrosion resistance and wind resistance to ensure its reliability and safety in various environments.

- Convenience of operation: The ease of operation of a marine crane is very important for crew members. When choosing a marine crane, you need to consider whether its operating interface is simple and easy to use, and whether it has good human-computer interaction, so that the crew can easily master the operating skills. In some special cases, the simple operation of the marine crane can also allow the crew to respond to emergencies more quickly.

- Ease of maintenance: We need to consider the maintenance work of the crane after long-term use. The crane should be easy to use and maintain, so that it is convenient for the crew to operate and maintain it. Therefore, it is recommended to choose a better manufacturer and a crane product that is relatively simple and convenient to maintain, so that the cost of repairing and replacing parts will be reduced, and maintenance will be simpler and faster.

- Cost-effectiveness: On the premise of meeting the function, quality and safety, price is another important factor in choosing a marine crane. Reasonable prices can help shipping companies reduce costs while ensuring efficiency and safety.

Based on the above factors, analyze the marine cranes suitable for different types of ships:

- Bulk carrier: For cargo ships that need to load a large amount of cargo, it is more appropriate to choose a marine crane with a higher load capacity and a larger working range. This ensures that the cargo ship can load and unload cargo efficiently and meet the weight requirements of the cargo.

- Large container ships: The crane used for large container ships needs to have a high load capacity and a large working range to meet the needs of ship loading and unloading. And it usually has a fast lifting speed and flexible operation performance to improve loading and unloading efficiency, as well as equipped with safety devices such as overload protection system and anti-capsulation device to ensure the safety of the operation process.

- Tankers: Tankers usually need to load and unload liquid cargo transport ships for bulk petroleum or refined oil. Therefore, marine cranes with good corrosion resistance, explosion-proof, earthquake resistance and wind resistance can be selected to ensure its reliability and safety in the marine environment.

- Fishing boats: Fishing boats usually need to load and unload caught fish and other seafood. Generally, fishing boats are small in size, so it is more appropriate to choose marine cranes with a small working range and convenient operation to facilitate the fishing boat crew to load and unload cargo. In addition, fishing boats need to work in harsh sea conditions, so the stability and safety of the crane are particularly important.

5. Yachts: Yachts are ships with entertainment and leisure as their main purpose, requiring cranes to not affect the comfort of passengers when loading and unloading cargo. Small telescopic cranes are portable and flexible. They can be used when needed and folded away when not needed, without taking up too much space.

Contact Information for Crane Base and Components Inquiries

For more information about Crane Base and Components or to obtain customized solutions, please contact us:

- Contact Person: Frank

- Tel: 86-510-82305188-8060

- Mobile: 86-18605101203

- Mail: frankgu@cmecwuxi.com

- Address: 15-16F, Building A10, No. 777, JianZhu West Road, Binhu District, Wuxi, Jiangsu, 214072. P.R. China

We look forward to collaborating with you and providing robust support and services for your business.