Introduction

Welding services are essential in modern manufacturing, enabling the creation and repair of robust and durable components. As a critical process in various industries, welding ensures the structural integrity and performance of parts used in sectors such as automotive, aerospace, construction, and marine. With the increasing demand for high-quality, customized welding solutions, companies need to adopt advanced techniques and maintain stringent quality standards. China Machinery Engineering Wuxi Co., Ltd. specializes in providing top-notch welding services tailored to meet the unique needs of diverse industries. Our expertise in various welding methods, combined with our commitment to precision and quality, allows us to deliver superior welding solutions that enhance the reliability and performance of our clients’ products.

Types of Welding Techniques

Welding is a versatile process with multiple techniques available to suit different materials and applications. The most commonly used welding techniques include:

MIG Welding (Metal Inert Gas): This method uses a continuous wire feed as an electrode and an inert gas to protect the weld pool from contamination. MIG welding is known for its speed and ease of use, making it ideal for welding thin to medium-thickness materials in automotive, construction, and fabrication industries.

TIG Welding (Tungsten Inert Gas): TIG welding uses a non-consumable tungsten electrode and an inert gas to produce high-quality, precise welds. It is suitable for welding thin materials and is commonly used in applications requiring superior weld quality, such as aerospace, medical devices, and food processing equipment.

Stick Welding (Shielded Metal Arc Welding): This technique involves using a consumable electrode coated in flux to lay the weld. It is highly versatile and effective for welding thicker materials and is often used in construction, pipeline, and repair work.

Laser Welding: Utilizing a high-energy laser beam, laser welding offers excellent precision and control. It is ideal for applications requiring minimal thermal distortion and high-speed welding, such as electronics, medical devices, and fine mechanical components.

Each welding technique has its advantages and is chosen based on the specific requirements of the project, including material type, thickness, and desired weld quality.

Customization and Precision

China Machinery Engineering Wuxi Co., Ltd. excels in delivering customized welding solutions tailored to the specific needs of various industries. Our approach to customization and precision includes:

Custom Welding for Unique Parts: We understand that each project has unique requirements, and we offer tailored welding services to meet those needs. Whether it’s a complex assembly or a specialized repair, our team is equipped to handle diverse welding challenges.

Precision Welding for High-Quality Results: Our commitment to precision ensures that every weld we produce meets the highest standards of quality and durability. We utilize advanced welding equipment and techniques to achieve exacting tolerances and superior weld integrity.

Examples of Custom Projects: We have successfully completed numerous custom welding projects across various industries. For instance, we have provided specialized welding services for automotive components, ensuring enhanced performance and longevity. In the aerospace sector, our precise welding techniques have been crucial in manufacturing high-strength, lightweight parts.

Advanced Technology and Equipment: Our state-of-the-art welding facilities are equipped with the latest technology, including CNC welding machines, robotic welding systems, and advanced welding simulators. This allows us to deliver consistent, high-quality welds with minimal human error.

Experienced Welding Professionals: Our team of skilled welders has extensive experience and training in various welding techniques. They are adept at handling complex welding tasks and ensuring that every project is completed to the highest standards.

By offering customized and precise welding solutions, we help our clients improve their product quality, reduce downtime, and enhance overall operational efficiency.

Industries Served

Our welding services cater to a wide range of industries, each with specific requirements and challenges. Key industries we serve include:

Automotive Industry: Welding is crucial in the automotive sector for manufacturing and repairing vehicle components such as frames, exhaust systems, and engine parts. Our precision welding services ensure that these components meet stringent safety and performance standards.

Aerospace: In the aerospace industry, the need for high-strength, lightweight materials requires advanced welding techniques. Our TIG and laser welding services are ideal for creating reliable, high-quality aerospace components that can withstand extreme conditions.

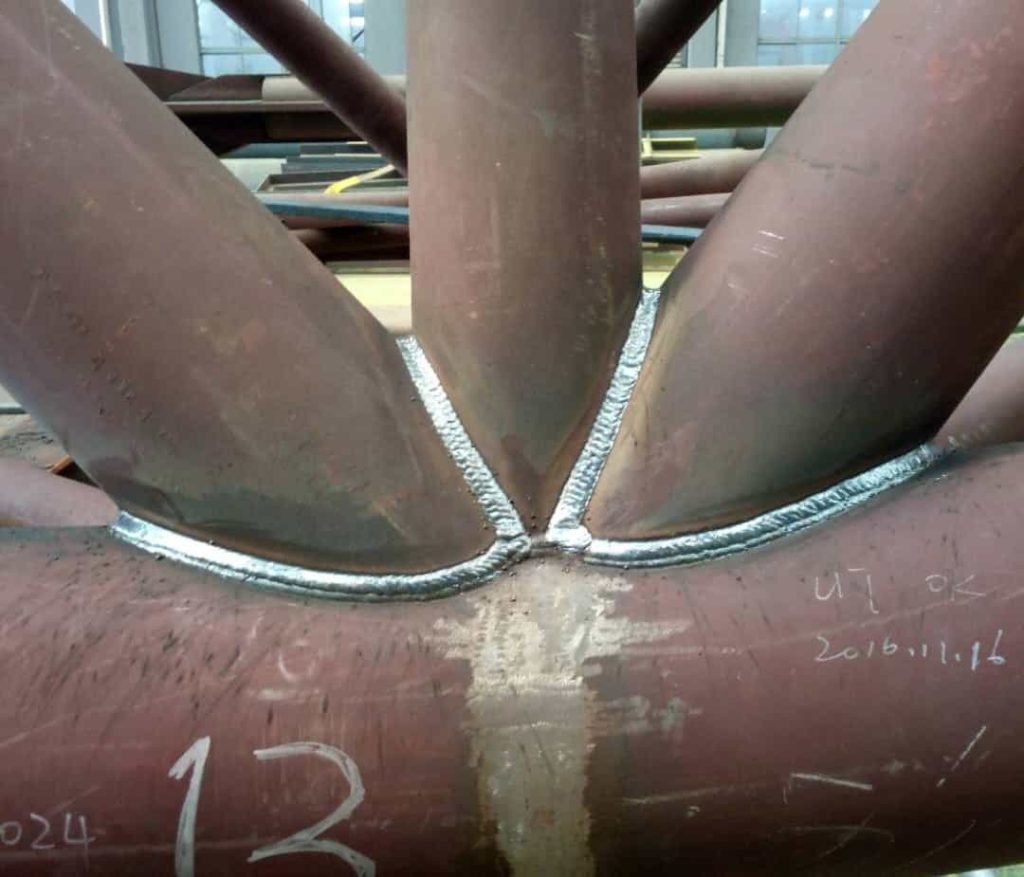

Construction: The construction industry relies on welding for the fabrication and assembly of structural elements, including beams, columns, and supports. Our robust welding solutions ensure the structural integrity and durability of construction projects.

Marine Industry: Marine applications require welding techniques that can withstand harsh environments and corrosion. Our welding services are tailored to meet the demands of the marine industry, providing durable and reliable welds for ships, offshore platforms, and underwater structures.

By serving these and other industries, China Machinery Engineering Wuxi Co., Ltd. ensures that our clients receive high-quality welding solutions that enhance their products’ performance and longevity.

Quality Assurance

At China Machinery Engineering Wuxi Co., Ltd., we prioritize quality assurance in every aspect of our welding services. Our comprehensive quality control program includes stringent inspection and testing procedures to ensure that every weld meets the highest standards of quality and safety. We adhere to international certifications and standards, such as ISO 9001, to guarantee the reliability and performance of our welding solutions. Our quality assurance processes include non-destructive testing (NDT), weld inspection, and performance testing, ensuring that our clients receive welds that are both strong and reliable.