Introduction of Heat Exchangers

Heat exchangers are vital components in various industries, playing a crucial role in thermal management systems. These devices facilitate the efficient transfer of heat from one medium to another, enabling processes such as heating, cooling, and energy conservation. Their applications span across multiple sectors, including power generation, HVAC systems, chemical processing, and the automotive industry. As industries evolve and demand more efficient and customized solutions, the need for advanced heat exchanger designs and manufacturing capabilities grows. Our company specializes in providing tailored heat exchanger solutions that meet the specific needs of diverse industries, ensuring optimal performance and energy efficiency. By leveraging cutting-edge technology and a deep understanding of thermal dynamics, we offer bespoke heat exchangers that enhance operational efficiency and contribute to sustainable practices.

Types of Heat Exchangers

Heat exchangers come in various types, each designed to meet specific operational requirements and constraints. The most common types include:

Shell and Tube Heat Exchangers: These are widely used due to their robust design and high efficiency. They consist of a series of tubes, one set carrying the hot fluid and the other the cold fluid, facilitating heat transfer between them. Their versatility makes them suitable for high-pressure applications in industries such as oil refining and chemical processing.

Plate Heat Exchangers: Known for their compact design and high heat transfer efficiency, plate heat exchangers use a series of thin, corrugated plates stacked together. They are ideal for applications where space is limited and are commonly used in HVAC systems, refrigeration, and food processing.

Air-Cooled Heat Exchangers: These exchangers use air to cool the process fluid, eliminating the need for water. This makes them an excellent choice for environments where water is scarce or costly. They are frequently used in power plants, petrochemical facilities, and natural gas processing plants.

Each type of heat exchanger has its unique advantages and is selected based on factors such as thermal efficiency, cost, space availability, and the nature of the fluids involved.

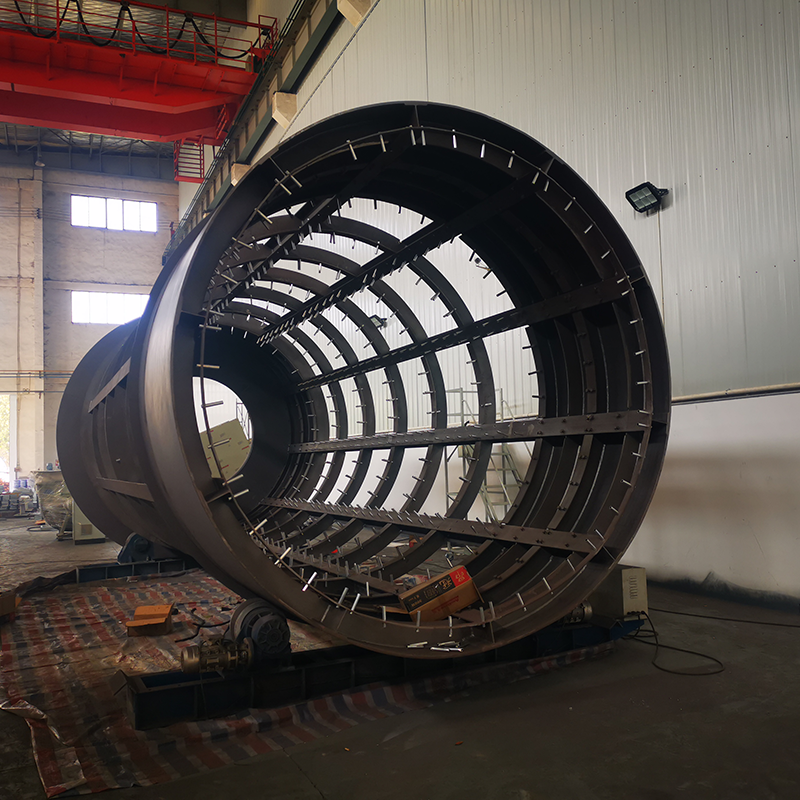

Custom Manufacturing Capabilities

Our company excels in customizing heat exchanger designs to meet the specific needs of various industries. By understanding the unique requirements of each application, we can develop heat exchangers that offer optimal performance and longevity. Our custom manufacturing capabilities include:

Design Flexibility: We offer a wide range of design options, from different configurations and sizes to various materials such as stainless steel, copper, and titanium. This flexibility allows us to cater to diverse thermal management needs across different sectors.

Advanced Manufacturing Techniques: Utilizing state-of-the-art technology, including computer-aided design (CAD) and computer-aided manufacturing (CAM), we ensure precision and accuracy in every heat exchanger we produce. Our advanced techniques enable us to create complex geometries and enhance the overall efficiency of the heat exchangers.

Materials Expertise: The choice of material significantly impacts the performance and durability of a heat exchanger. We have extensive expertise in selecting and sourcing the best materials for each application, considering factors such as corrosion resistance, thermal conductivity, and mechanical strength.

Quality Assurance: Our rigorous quality control processes ensure that every heat exchanger meets the highest standards of performance and reliability. We conduct thorough testing and inspections at every stage of production to guarantee the final product’s integrity and efficiency.

By providing customized heat exchanger solutions, we help our clients achieve better energy efficiency, reduced operational costs, and improved overall system performance. Our commitment to quality and innovation positions us as a leading provider of bespoke thermal management solutions.

Applications in Various Industries

Heat exchangers are indispensable in numerous industries due to their ability to efficiently manage thermal energy. Key applications include:

Power Generation: Heat exchangers are critical in power plants, where they are used in processes such as condensing steam and preheating feedwater, enhancing overall efficiency and reducing energy consumption.

HVAC Systems: In heating, ventilation, and air conditioning systems, heat exchangers facilitate the transfer of heat between indoor and outdoor environments, contributing to comfortable and energy-efficient living and working spaces.

Chemical Processing: Chemical plants rely on heat exchangers to control reaction temperatures, recover heat from process streams, and ensure safe and efficient operations.

Automotive Industry: Heat exchangers play a vital role in automotive applications, including engine cooling, air conditioning, and exhaust gas heat recovery, helping to improve vehicle performance and fuel efficiency.

By serving these and other industries, our heat exchangers contribute to operational excellence and sustainability, making them an essential component of modern industrial systems.

Quality Control and Testing

Ensuring the highest quality standards is paramount in our heat exchanger manufacturing process. China Machinery Engineering Wuxi Co., Ltd. implements a comprehensive quality assurance program that includes rigorous testing and inspection procedures at every production stage. We employ advanced testing methods to assess the efficiency, durability, and safety of our heat exchangers, including pressure testing, thermal performance analysis, and corrosion resistance evaluation. Adhering to international standards and certifications, we guarantee that each heat exchanger meets or exceeds industry requirements, providing our clients with reliable and high-performing thermal management solutions.